What you’ll learn:

- How electric powertrains are fundamental to EV adoption, offering more reliable and longer-lasting mobility than gasoline engines.

- The role of traction inverters in safely, accurately, and efficiently controlling an e-motor for driving range, responsiveness, smoothness, traction, and handling.

- The technology behind the traction inverter.

- Technologies and solutions that reduce the cost of EVs, extend their driving range, improve the consumer experience, and offer a broader range of e-motor options.

- How the S32K39 MCU family addresses EV traction-inverter control needs with a combination of performance, integration, networking, security, and functional safety.

Several key factors are driving the dramatic shift to electric vehicles (EVs), with carmakers investing heavily in the electrification of their vehicles. Government regulations and incentives support a global push to reduce greenhouse gases. At the same time, consumer awareness and interest in EV benefits continues to climb as their cost drops. In addition, steps are being taken to address driving range anxiety and charging infrastructure is expanding.

The combination of those factors, along with the ramp up of EV penetration, has many market researchers predicting 50% of new vehicles sold annually will be electric by 2030.

The new electric powertrain is poised to offer more reliable and longer-lasting mobility with less maintenance thanks to the reduction of moving components—from the hundreds in an internal combustion engine (ICE) vehicle to ~20 in an EV.

A few critical components support the electric powertrain based on a high-voltage (~400 to 800 V dc) battery pack with a typical capacity of 40 to 200+ kW/h and one or more electric motors (e-motors). For instance, an on-board charger (OBC) converts ac power received through a charging point to dc and controls the battery charging. The battery-management system (BMS) continually monitors the state of the battery and ensures that it’s safely managed in case of a malfunction.

In addition, the dc-dc converter provides lower voltages like 12/24/48 V dc for other systems such as infotainment and body. And the traction inverter safely converts the battery’s dc energy to ac to control the e-motor torque to move the EV.

The Importance of the Traction Inverter

The traction inverter is a key component at the heart of the EV powertrain, directly impacting battery power and, ultimately, the consumer driving experience. It’s responsible for safely, accurately, and efficiently controlling an e-motor for driving range, responsiveness, smoothness, traction, and handling.

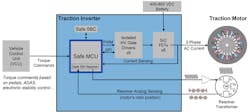

Traction inverters integrate many technologies to interpret torque commands from a vehicle control unit (VCU) and safely control the e-motor as needed. Let’s take a closer look at the end-to-end, real-time control loop (Fig. 1).

Anatomy of the Traction Inverter

A vehicle’s motion depends on multiple torque demand inputs, such as the state of the accelerator and brake pedals, electronic stability control, and ADAS features like automatic emergency braking and adaptive cruise control.

Based on these inputs, a VCU calculates and sends torque values to the traction inverter through a CAN or Ethernet interface to a safe microcontroller (MCU). In EVs with multiple e-motors, the VCU can provide torque vectoring to intelligently and accurately adjust each motor’s torque for improved handling and traction.

A safe, high-performance MCU is the brain of the e-motor control, performing math-intensive, field-oriented control (FOC) to efficiently control torque based on the motor’s rotor position and current demand of the three (or six) ac current phases. A safe, software resolver determines the motor’s exact rotor position and speed, intelligently decoding the sine and cosine signals produced by a resolver transformer that spins with the rotor.

The three AC current phases are sensed and sampled by MCU analog-to-digital converters (ADCs). With this information, the MCU computes pulse-width-modulated (PWM) control signals corresponding to meet the torque demand and sends them to isolated, high-voltage gate drivers that control power switches to convert the battery’s dc power to ac power.

Six isolated high-voltage gate drivers, one for the high side and one for the low side for each of the three ac phases, deliver safe control, monitoring, and protection of the power switches to maximize efficiency and reliability.

For safety, the drivers provide galvanic isolation from the low-voltage control side and the high-voltage switching side, and they discharge the dc-link capacitor when the vehicle is off or about to crash to prevent electrical shock. Intelligent gate drivers offer features that improve power efficiency and incorporate monitoring and protection circuitry for rapid fault detection and increased safety.

The power switches typically used today are insulated-gate bipolar transistors (IGBTs). However, wide-bandgap (WBG) power switches, such as emerging silicon carbide (SiC) and gallium nitride (GaN), can provide significant benefits with higher switching rates that lead to higher efficiency and power density, as well as smaller supporting components to reduce the size of the e-motor. As switching frequencies increase from tens of kilohertz with IGBTs to 100 to 200+ kHz with WBG power switches, it will require higher-performance MCUs.

Opportunities to Improve Traction Inverters

Figure 2 shows some of the major EV market trends. Improvements to traction inverters can address them to accelerate consumer acceptance and improve satisfaction.

Leveraging modern silicon technologies and solutions enables carmakers to lower EV cost, extend driving range, improve the driving experience, and offer a broader range of e-motor options with a scalable approach. New innovations in MCUs, gate drivers, and power switches can improve EV metrics like battery cost, power density, and efficiency and offer additional safety features.

Higher-performance processing will be able to support new motor-control innovations, such as back electromotive-force (EMF) sensorless control for further cost reduction. Traction-inverter designs also can be extended to support new vehicle E/E zonal architectures and data-driven, software-defined vehicles that lead to the “software-defined motor.” And they can improve over time with over-the-air (OTA) updates.

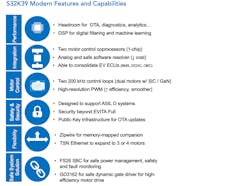

On that front, NXP Semiconductors introduced new EV solutions that address market trends and opportunities. The S32K39 series MCUs are optimized for dual traction-inverter control with four Arm Cortex-M7 cores at 320 MHz configured as a lockstep pair and two split-lock cores, along with two motor-control coprocessors and a digital signal processor (Fig. 3).

They can support two 200-kHz control loops for today’s IGBT, as well as emerging SiC and future GaN power switches, for improved power efficiency and higher switching rates. In turn, they reduce motor size, weight, and cost, which can increase driving range.

Alternatively, a single, six-phase motor can be supported for higher reliability and availability, which is important for higher-duty-cycle EVs like mobility and commercial fleets. Enough Arm processing is available to manage new, data-driven use cases as well, which can extend to the cloud for digital twins and machine-learning needs, along with OTA support to implement a software-defined motor.

With S32K39 analog integration and support for a safe software resolver, external discrete components and the resolver-to-digital converter can be removed to lower system cost. Combining the MCU with the company’s FS26 safety system basis chip (SBC) and GD3162 high-voltage isolated gate drivers creates an ASIL D dual traction-inverter system.

An S32K39 MCU can run standalone to control dual traction inverters. Or it could be used as a remote smart actuator via time-sensitive-networking (TSN) Ethernet to extend to three or four motors when combined with NXP’s S32E real-time processor, serving as an EV propulsion domain controller in addition to controlling two additional traction inverters.

Leveraging TSN allows for time synchronization (IEEE 802.1AS-Rev), redundancy for safety (IEEE 802.1CB), and quality of service (IEEE 802.1Qbu and IEEE 802.1Qbv) that are needed for reliable control across the vehicle as well as for zonal architectures. TSN is essential for real-time applications that require predictable latency and bandwidth.

Conclusion

The rapidly growing EV market brings new opportunities and challenges. The traction inverter plays a critical role as the heart of the electric powertrain that will power most new vehicles by the end of the decade.

Many improvements can be made with innovations in MCUs, gate drivers, and power switches that can directly impact battery life and driving experience, let alone increase consumer acceptance. Support for new technologies is key to scale EVs faster and improve them over time, leveraging the software-defined vehicle infrastructure that’s being developed by the automotive industry.

NXP has entered the fray with the S32K39 MCU for dual traction-inverter control. The MCU offers a combination of capabilities to enable future improvements, and it can be paired with the S32E real-time processor to scale up to four e-motors.