What’s the Latest in GaN-Based Automotive Applications?

Members can download this article in PDF format.

What you'll learn:

- GaN-inspired advances in on-board battery chargers.

- How AlGaN/GaN HEMTs deliver high switching frequencies.

- Buck converter reference design for 48-V apps that leverages GaN FETs.

Electric vehicles (EVs) are gaining popularity as savvy consumers, especially in California, recognize the advantages of excellent acceleration performance that can leave gasoline-powered vehicles in the dust, say, when a traffic light turns green. This is due to electric motors producing their peak torque the moment drivers step on the accelerator. However, the primary motivation for an EV over an internal-combustion-engine (ICE) vehicle is energy efficiency.

EV On-Board Battery Chargers

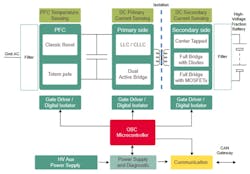

On-board battery chargers (OBCs) for EVs1 are fully capable of recharging high-voltage traction batteries from the AC power grid (Fig. 1). The parked vehicle plugs into one of the EV Level 1 and Level 2 AC charging stations that are popping up in parking lots, homes, companies, shopping centers, and other locations dotting the landscape.

7.2-kW OBC by Canoo

This solution from Canoo uses Infineon’s (formerly GaN Systems) power semiconductors. It has an efficiency of 98.7% power factor correction (PFC) peak with low switching losses, small footprint, and efficient power management (Fig. 2).

GaN-Based 6.6-kW OBC Reference Design

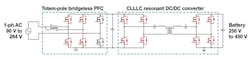

This gallium-nitride (GaN)-based bidirectional OBC reference design7 features an application from a universal single-phase input off the AC power grid. It provides full output power (6.6 kW) to the load with an input voltage of 208 V AC and higher (Fig. 3).

The key feature of this reference design is to deliver the highest power to the vehicle battery. In addition, there’s a power-density level higher than 60 W/in.3 (3.66 kW/L) with a traction battery voltage range of 250 to 450 V. This OBC design will support bidirectional operation.

The PFC stage along with the DC-DC converter utilizes 30 mΩ, automotive-qualified, 650-V LMG3522R030-Q1 GaN FETs controlled by a Texas Instruments C2000 TMS320F28388D real-time microcontroller (MCU). The converters use 12 GaN FETs while the low-frequency FETs, for the bridgeless input rectifier, are simply regular silicon MOSFETs.

GaN-on-Si Power HEMTs for Automotive

The GaN high electronic mobility transistors (HEMTs) are based on the AlGaN/GaN structure.2 This makes it possible to have a low on-resistance with high switching frequencies thanks to the characteristics of the electron channel.

An AlGaN/GaN HEMT is a normally-on device. However, this isn’t convenient for fail-safe power applications, which need normally-off power switches. To transform the AlGaN/GaN HEMT into a normally-off device, two different methods are widely adopted:

- The use of a cascode configuration, in which a fast and small-sized silicon transistor is employed to drive the normally-on HEMT cascode transistor.

- The use of a p-GaN gate—a p-doped GaN layer is grown on the AlGaN/GaN stack, pulling up the bands while depleting the two-dimensional electron gas (2DEG) below the gate contact.

Modern GaN power switches are based on these two topologies, which are fabricated on a large-size silicon substrate.

Though NexGen recently announced GaN JFETs for commercialization in the 700- to 1200-V range, the wider commercialization and higher maturity level of AlGaN/GaN HEMTs are currently preferred for automotive applications.

Designers must distinguish the various vehicle topologies currently present in the market. Each of these topologies include different building blocks from a power electronics point of view:

- Mild hybrid vehicles: These vehicles have a 48-V battery and a 12-V battery connected via a DC-DC converter. The 48-V battery doesn’t have any unique action for the vehicle traction. That’s because the electric motor is employed together with just the combustion engine. Also, this topology is unable to externally charge the 48-V battery. The high-voltage battery capacity is limited to 0.5 kWh.

- Conventional hybrid vehicles: These vehicles have a high-voltage battery (typically in a voltage range from 100 to 250 V) that’s employed together with a standard 12-V battery. These two are connected by DC-DC converters. The electric motor is able to function on the vehicle traction even in the absence of the combustion engine. Battery capacity can run as high as 3 kWh and will not be externally charged.

- Plug-in hybrid vehicles: Similar to conventional hybrids (12-V standard battery and DC-DC converter are present, electric motor can act alone) but with bigger and higher capacity traction batteries (voltage range up to 400 V, capacity up to 18 kWh, possibility to be externally charged).

- Full-electric vehicles: Absence of combustion engine, with traction due to electric motor only. Battery voltages aren't lower than 400 V, with some models reaching 800 V. Battery capacity typically goes up to 100 kWh, though recent pickup truck applications have significantly higher energy-storage capacity. 12-V battery and DC-DC converter are still present.

GaN FETs in a Dual-Phase Buck Converter Ref Design for 48-V Automotive Apps

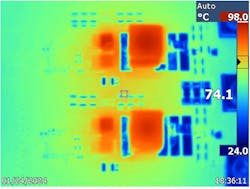

In this automotive reference design (PMP23392),3 there are four 100-V, 97-A LMG3100R017 GaN FETs with an integrated driver. The GaN FETs are configured in a dual-phase, interleaved, synchronous buck controller design. The converter has a 5-V regulated output at 30 A with a peak current of 60 A. The input voltage needs to be 24 to 60 V with a nominal voltage of 48 V. The thermal image is shown in Figure 4.

Other GaN Automotive Applications

- Automotive GaN FETs engineered for high frequency and robustness in HEV/EVs.5

- In 2020, Texas Instruments introduced the electronic industry's first automotive GaN FET with an integrated driver, active power management,6 and protection.

- The Infineon traction inverter converts DC to AC voltage for the traction motor. GaN transistors achieve greater energy efficiency, which leads to more than 5% extended vehicle driving ranges (Fig. 5).

- Infineon high-voltage DC-DC converters with GaN are quite efficient, with less losses and less wasted power to heat. These high-power-density DC-DC converters lead to lower vehicle weight along with a smaller system size.

The Rise of GaN in EV System Design

GaN has become increasingly important in EV design. GaN power devices enable high power density, longer-range vehicle capability, smaller size, and higher efficiency, leading to overall lower EV system cost.

Read more articles in the TechXchange: Gallium Nitride (GaN).

References

1. On-board battery charger (OBC) for electric vehicles, Infineon.

2. “GaN-on-Si Power HEMTs for Automotive: Current Status and Perspectives,” D. Favero, A. Marcuzzi, C. De Santi, G. Meneghesso, E. Zanoni and M. Meneghini, AEIT 2023.

3. “Test Report: PMP23392 Dual-Phase Buck Converter Reference Design Using GaN FETs for 48V Automotive Applications,” TIDT388, Texas Instruments, 2024.

4. Surround view system ECU, Automotive camera, Texas Instruments.

5. “Automotive GaN FETs Engineered for High Frequency and Robustness in HEV/EVs,” Technical article, SSZT220, November 2020.

6. “TI introduces industry's first automotive GaN FET with integrated driver, protection, and active power management,” 2020.

7. “Optimizing GaN-Based High-Voltage, High-Power Designs,” Brent McDonald, Markus Zehendner, Texas Instruments, 2022.

8. “GaN devices for automotive application and their challenges in adoption,” Tetsu Kachi, IEEE 2018.

About the Author

Steve Taranovich

Freelance Technical Writer, Phoenix Information Communication LLC

Steve is a contributing editor to Electronic Design.

Author of the non-fiction “Guardians of the Right Stuff,” a true story of the Apollo program as told by NASA and Grumman Corp. engineers, an astronaut, and technicians.

Experienced Editor-In-Chief of EETimes/Planet Analog and Senior Technical Editor at EDN running the Analog and Power Management Design Centers from 2012 to 2019.

A demonstrated history in electronic circuit design and applications for 40 years, and nine years of technical writing and editing in industry. Skilled in Analog Electronics, Space-related Electronics, Audio, RF & Communications, Power Management, Electrical Engineering, and Integrated Circuits (IC).

1972 to 1988 worked as a circuit design engineer in audio (8 years) and microwave (8 years). Then was Corporate Account Manager/applications engineer for Burr-Brown from 1988 to 2000 when TI purchased Burr-Brown. Worked for TI from 2000 to 2011.

Strong media and communication professional with a BEEE from NYU Engineering in 1972 and an MSEE from Polytechnic University in 1989. Senior Lifetime member of IEEE. Former IEEE Long Island, NY Director of Educational Activities. Eta Kappa Nu EE honor society member since 1970.