Pressures Mount to Improve EV Manufacturability

With wavering support for electric-vehicle (EV) subsidies in some jurisdictions as well as fierce competition, improving manufacturability of EVs is a critical responsibility of electronic design engineers.

It’s also a timely area of focus with EV production scaling up and consumer demands for increased quality, reliability, and cost efficiency. Strategies must address areas as diverse as component integration, assembly simplification, diagnostic support, and compliance with automotive standards.

Design-for-Manufacturability (DFM) Basics

The goal of design for manufacturing (DFM) is to optimize design for ease of assembly, testing, and consistency in volume production. It starts with a focus on some classic best practices.

First, minimize part count when possible. For example, employing higher levels of integration in chips and modules can reduce wiring and connectors and it may also be less expensive. When the opportunity arises, standardize components within a given vehicle or across a product line. This can take time, planning, and discipline, but it also has obvious benefits in terms of procurement, stock keeping, and beyond. If possible, aim for common packages and voltages to further streamline sourcing and assembly.

Manufacturability can also be boosted by adopting modular design, including easily swappable PCBs or control modules (e.g., for BMS, inverters, or infotainment). Bedrock PCB design should also support automated assembly as much as possible. For instance, ensuring consistent pad sizes, component orientation, and fiducials can help automated surface-mount technology (SMT) machines operate at an optimum pace with minimal chance for errors.

Engineering practices also play a role in reducing the potential for rework, which is always an expensive proposition. Possible issues to avoid include risky, tightly packed high-voltage traces, the marginal placement of components prone to thermal stress, or buried vias.

>>Download the PDF of this article

Buried vias are a double-edged sword, enabling more complex PCBs but possibly increasing manufacturing costs due to the additional drilling and plating steps required. They can also create heat concentration points within the board. Furthermore, the aspect ratio (depth to diameter) of buried vias needs careful consideration to avoid structural weaknesses or connection problems.

How Can Design for Testability (DFT) Help with Manufacturability?

You can and should design in reliability, but there’s no substitute for testing. Making testing easy, fast, and reliable at both PCB and system levels makes testing more cost-effective and useful. This can meld with other manufacturability actions, such as the idea of watching pad sizes, component orientation, and fiducials in PCB designs.

Those actions enhance manufacturability, but they can also support automated optical inspection (AOI). That’s most effective when adequate clearances are available on a board or in an assembly and when labeling is suitable for machine vision.

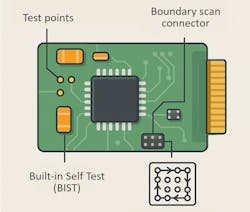

Diving deeper into DFT means including built-in test points and test buses (e.g., JTAG, CAN diagnostic access) and integrating built-in self-test (BIST) in ASICs or microcontrollers (see figure).

Three further DFT options are boundary-scan chains, segment testable subsystems, and error reporting capabilities. Design-in boundary-scan chains can allow for easier in-circuit test (ICT). Boundary-scan chains use a serial path of registers connected to each pin of the integrated circuits. This allows for stimulating and observing signals at the pins, enabling the testing of connections and functionality without direct physical access to the pins.

Similarly, implementing segment-testable subsystems where individual components or sections of a larger system can be tested independently can help. This can allow, for example, isolated testing of inverter, charger, or a high-voltage battery interface.

Error reporting in electronic testing refers to the mechanisms used to identify and communicate errors detected during testing. This is separate from BIST — error reporting is a broader concept that encompasses various methods, while BIST is a particular implementation focused on self-testing capabilities such as diagnostic trouble codes (DTCs), checksum, and watchdog verification.

How Can Design for Assembly (DFA) Improve Manufacturability?

Another angle on DFM is design for assembly (DFA), which focuses on ensuring components and subsystems are easy to assemble with minimal tooling and human error. This boils down to a lot of common-sense practices, including:

- Using keyed connectors and polarity-proof interfaces to prevent miswiring.

- Eliminating hand-soldering and prioritizing surface-mounting over through-hole components unless structurally necessary.

- Minimizing wire harness complexity, for example, by using flexible PCBs or busbars in place of discrete wiring where possible.

- Pre-assembly and testing of subsystems such as PCB with cooling and HV isolation integrated before vehicle integration to reduce late-stage rework.

- Integrating passive cooling designs (e.g., heatsink-compatible layout) to reduce system complexity.

Where Does Cost and Reliability Optimization Fit in DFM?

A goal of DFM is to reduce material and production costs without compromising quality or performance. Additional optimization tactics can include:

- Specifying automotive-grade components with long lifecycles and robust qualification (AEC-Q100, ISO 16750).

- Selecting components with multiple sources to mitigate supply-chain risks.

- Performing thermal and EMI simulations early can reduce expensive late-stage redesigns.

Some final DFM considerations include keeping a view of the full EV environment. Make sure you’re compliant with regard to EMI/EMC and anticipate the need for filtering, shielding, separating HV and LV domains, and grounding.

You could also aim to embed diagnostics and failsafe logic within electronic control units (ECUs) for predictive maintenance and safety and design-in firmware upgradability. Lastly, sustainability and growing regulatory requirements related to sustainability make it prudent to include disassembly and recycling considerations in your DFM efforts. It can be hard to look that far into a product’s lifecycle, but it’s a necessary consideration.

References

The Roadmap to Electric Vehicle Manufacturing

How does EV Manufacturing and Design differ from Traditional Vehicles?

>>Download the PDF of this article

About the Author