Flexible Coating Boosts Solid-State Battery Performance in Extreme Conditions

What you'll learn:

- The silver-based coating adapts to changes in battery structure, reducing the risk of cracking or delamination.

- Silver enhances ionic conductivity, improving overall battery performance.

- The coating maintains stability and effectiveness in high- and low-temperature environments.

The surge in demand for electric vehicles (EVs) has spurred automotive manufacturers to intensify their focus on improving battery performance. Engineers have for years envisioned solid-state batteries as the future of electric vehicles, with their promise of enhanced safety, increased power and extended lifespan. Unlike conventional lithium-ion cells, solid-state batteries store more energy and use solid electrolytes instead of flammable liquids, resulting in a reduced risk of overheating and fire hazards.

Nevertheless, progress toward mass production has been slow. That’s because these batteries tend to crack and lose performance during fast charging or in freezing weather with slower than desirable lithium-ion transport and the resulting lithium dendrites.

Even when the ionic conductivity of composite solid-state electrolytes is increased to meet the required performance targets, it’s still difficult to realize long-life cycling of solid-state batteries at a sufficiently high current density and areal capacity.

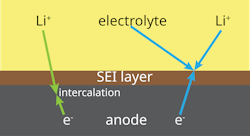

Issues with the SEI Layer

The quality of the SEI significantly influences battery performance, including charge loss, rate capability, the ability to cycle, and safety. It typically has a hard, brittle nature, making it susceptible to cracking under stress.

These cracks can lead to uneven lithium buildup within the battery, accelerating degradation. Once fractured, it causes uneven lithium buildup, leading to faster degradation and shorter battery life.

A Ductile Solid Electrolyte Interphase

Automakers are working on all kinds of different solutions, and research into solid-state batteries continues on without pause. Recently, scientists from Tsinghua University’s Shenzhen International Graduate School and Tianjin University have developed what they call a “flexible armor” layer. It’s designed to reinforce the battery's surface and bolster its resilience to help endure stress and maintain performance even in freezing conditions.

In the paper “A ductile solid electrolyte interphase for solid-state batteries,” published Oct. 29, 2025, in the journal Nature, professors Feiyu Kang and Yanbing He from the Shenzhen International Graduate School, together with Professor Quanhong Yang from Tianjin University, discuss a new approach to improving solid-state batteries by making them more flexible rather than harder.

Using silver-based materials Ag2S and AgF, the researchers developed a flexible SEI layer that can bend slightly without breaking, maintaining a stable structure while still facilitating the movement of lithium ions. An SEI acts as a protective barrier, preventing further electrolyte decomposition.

This new hybrid architecture helps distribute mechanical stress more evenly across the battery, preventing cracks and structural failure while keeping lithium ions uniformly spread out during charging and discharging.

Test Results of the New SSB Flexible SEI Layer

During laboratory tests, the team’s newly designed solid-state batteries showed notable endurance and stability, surpassing conventional designs. The lab results showed continuous operation for over 4,500 hours under high-stress conditions, demonstrating the coating's ability to resist cracking and degradation over extended periods.

The researchers also found that the batteries maintained stable performance for over 7,000 hours at a temperature of −30°C, a temperature that would cripple typical solid-state cells.

The design combines both soft and stiff materials in a gradual, layered structure. This reduces internal stress, prevents cracks, and keeps lithium evenly distributed during charging and discharging.

Next Steps to Overcome SEI Coating Challenges

Still, significant work remains. The scientists emphasize that this innovation is not a quick path to mass production. Scaling is the next test. Silver compounds aren’t a cheap option. Manufacturing must apply the coating consistently at high speed and over a large area. Layer thickness and uniformity will matter, too.

The research does, however, offer a potential pathway to improve solid-state battery reliability and lifespan under extreme conditions, which could pave the way for wider adoption in electric vehicles.