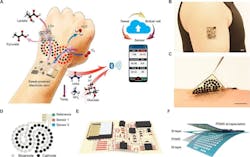

Using some form of energy harvesting to power personal medical devices that monitor body parameters is clearly an attractive proposition, but it’s difficult to realize in practice. Addressing this issue, a team based at the California Institute of Technology (Caltech) has developed a harvesting-powered electronic skin (e-skin) made from soft, flexible rubber that’s applied directly on top of the subject’s skin.

The e-skin contains embedded sensors and an active circuit comprising the entire signal chain, including analog front end (AFE) through Bluetooth link. It senses, monitors, and reports on vital signs such as heart rate, body temperature, and metabolic byproducts that are indicators of health.

By using a unique biofuel cell (BFC) powered by one of the body's own waste products—in this case, skin sweat—it bypasses the issues associated with battery life, passive RFID, or near-field communications. Called a perspiration-powered integrated electronic skin (PPES), it’s designed for on-skin, “in situ” multiplexed sensing of metabolic analytes (such as urea, NH 4⁺, glucose, and pH) and skin temperature during prolonged physical activities, wirelessly transmitting the acquired data to a user interface (Fig. 1).

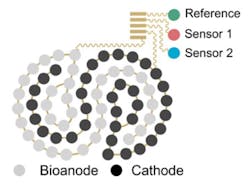

The PPES has two main parts: a chemical-electrical interface and the all-electronic circuitry (ICs, passives, and wireless link). The first part consists of a nanoengineered, flexible, electrochemical patch containing a BFC and biosensor arrays for energy harvesting and molecular analysis in human sweat, respectively, all on serpentine-connected electrode arrangement (Fig. 2). The unique design of the energy-harvesting BFCs leverage the specifics of human “sweat chemistry,” which contains very high levels of the lactate. Lactate is a chemical compound generated as a by-product of normal metabolic processes, especially by muscles during exercise.

The fuel cells, which are built into the e-skin, absorb that lactate and combine it with oxygen from the atmosphere, generating water and pyruvate, another by-product of metabolism. The biofuel cells are made from a 3D arrangement of carbon nanotubes impregnated with a platinum/cobalt catalyst and composite mesh holding an enzyme that breaks down lactate. (The transition metal cobalt is added to the platinum cathode catalyst to extend cathode life.)

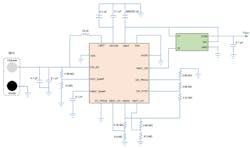

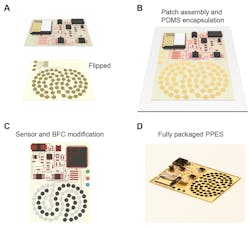

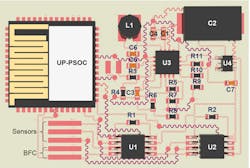

The second piece is a flexible electronic patch that consolidates the rigid electronics on an ultrathin polyimide substrate through flexible interconnects for power management, signal processing, and wireless transmission. The researchers also integrated a skin-interfaced microfluidic module with independent inlet-outlet design into the PPES, to achieve efficient fresh “sweat sampling” for stable BFC operation and accurate sweat analysis. The electronic components and the interconnects of the PPES are then encapsulated with polydimethyl siloxane (PDMS) to avoid sweat/electronic contact.

The harvesting circuit (Fig. 3) generates continuous, stable power at up to 3.5 mW/cm2 over multiple days in human sweat (the researchers claim it’s a record for this type of harvesting), with typical output at about 2 mW at half a volt; open-circuit voltage is 600 mV. Fuel-cell power is accumulated by a capacitor that charges cyclically between 1.5 and 3.8 V. System power consumption is approximately 100 μA at 3.3 V during deep sleep and peaks at about 10 mA during transceiver activity. Total “run time” at present is approximately 60 hours, after which the harvesting transducer is “exhausted.”

A sequence of assembly and encapsulation steps (Fig. 4) is needed to create the final patch (Fig. 5).

“We want this system to be a platform,” said project leader Prof. Wei Gao, of the Caltech Department of Medical Engineering. "In addition to being a wearable biosensor, this can be a human-machine interface. The vital signs and molecular information collected using this platform could be used to design and optimize next-generation prosthetics."

Full details, including concept, implementation, schematic, BOM, test results across multiple variables, and more are in their paper “Biofuel-powered soft electronic skin with multiplexed and wireless sensing for human-machine interfaces” published in AAAS Science Robotics (12 authors!), plus the extensive Supplementary Materials file. Funding for the research was provided by a California Institute of Technology startup grant, the Rothenberg Innovation Initiative (RI2) program, the Carver Mead New Adventures Fund, and the National Institutes of Health.