What you’ll learn

- The battery-drain risk of storing energy in batteries when a car is left stationary for a long time.

- How dc-dc buck converters can best serve switching regulators in terms of low quiescent current.

- A trio of energy-saving methods when using dc-dc converters.

Automotive vehicles are becoming more sophisticated, integrating more advanced electronics to provide new comfort features in the car and increase safety for drivers and passengers. As automakers add more functionality and thus more electronics, the automotive system has an increased need for electrical energy.

While some cars could use solar panels, energy generated in this way isn’t enough for propulsion, much less to support all of the new electrical features. Therefore, engineers must consider devices that support lower energy consumption in their designs.

Why Low Energy Consumption Matters

Most cars on the road today generate electrical energy by using an alternator connected to the internal combustion engine (ICE). This energy is stored in either a traditional lead-acid or lithium-ion battery, with the latter used increasingly in modern automotive systems. An obvious drawback of storing energy in a battery is that if the automobile is left stationary for a long time—for instance, in an airport parking lot—it’s possible for the battery to drain completely, necessitating a jump-start.

The energy draw of many microcontrollers (MCUs) causes the battery to drain—with a greater number of MCUs still monitoring various functions and features of the automobile when parked. Such functions can include occupancy detection for safety reasons using sensors like radar or cameras, detecting the owner approaching the vehicle due to smart key fobs either in their pocket or bag, and unlocking doors or allowing remote starting of the vehicle.

There are also green issues to consider. One byproduct of the ICE charging the battery is carbon dioxide and other fumes or toxins that result from the combustion process. Energy efficiency will affect future automotive architectures as automakers move to using batteries not just for propulsion, but for everything else. Not only will the car consume energy when stationary, but that energy won’t be replenished while in motion due to the removal of the alternator, with applications like the HVAC system, wipers, automatic windows, and more taking energy from the battery.

The Need for Energy Savings

Electronic control units (ECUs) operate the electronics inside a vehicle and control the car, whether it’s stationary (parked or stopped at traffic lights) or in motion. The number of ECUs in standby mode or always on will increase in the future, and the challenges of saving energy will get worse.

Most ECUs are based on a central MCU, an interface for communication, and power devices. In some cases, the communication bus can’t turn off the ECUs individually, only globally. This can mean that they’re not in full sleep mode and will consume energy. Automotive systems have to meet strict sleep-mode energy targets to increase battery life. Thus, power devices used in automotive designs must have the lowest possible energy use when in standby mode. The metric for this is quiescent current (IQ).

Using DC-DC Buck Converters to Optimize Energy Draw and IQ

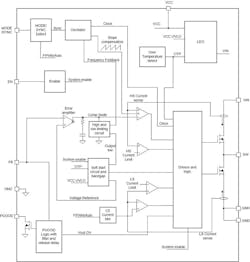

Modern switching regulators are often designed to draw the lowest possible energy from the system, while still maintaining the correct regulation and operation, especially as the system wakes up or when there’s a need for fast operation and power up. As an example, let’s look at the LMR36506-Q1 synchronous buck converter from Texas Instruments (see figure).

Some critical blocks of the LMR36506-Q1, like the internal bias, low-dropout regulator (LDO), transconductance amplifier, and voltage-reference blocks, need to remain on. For example, the transconductance amplifier, part of the control loop, is used to maintain output regulation. Critical control-loop components must remain active to ensure a fast response to a sudden load requirement and regulate the voltage at the load, so that they can’t be shut off. Otherwise, the regulation won’t be maintained correctly.

Thankfully, the energy that both LDOs and transconductance amplifiers consume while in operation is optimized to be at minimum when in sleep mode, and designed to go from low-power mode to normal mode quickly, accurately, and efficiently. In addition, the soft-start and bandgap reference blocks are designed with low energy consumption and low IQ in mind; if they’re not, these blocks would need more complicated on/off circuits to react to the change in the load profile.

The LDO, inherently efficient by nature, also provides a clean supply. The LDO is the main power supply for the internal circuitry of the switching converter and creates the dc collector supply voltage (VCC), which is used for many of the internal blocks. One example would be the drivers for the output metal-oxide semiconductor field-effect transistors (MOSFETs). The driver for the MOSFETs needs to source and sink current from the VCC. The VCC is used to charge the boot capacitor for the high-side MOSFET.

The LDO also needs to offer good stability, a good power-supply rejection ratio, and accuracy to operate correctly, which becomes more difficult as you lower its energy consumption. LDO energy consumption requirements can vary with the output power of the switching converter as the MOSFETs increase in size; typically, with smaller converters, it’s easier to meet lower standby energy consumption.

For example, the LMR36506-Q1 can switch the internal LDO on and off to save power. After the switching regulator starts up, you could feed the output voltage back to a bias pin that’s input to the LDO. Because the conversion voltage is smaller from the output voltage (VOUT) to VCC, you can save lots of power by not using the input voltage (VIN) to source energy.

Operational Conditions to Achieve Lower IQ for the Buck Converter

Although device selection will influence the energy consumption of your design, consider implementing these methods for saving energy when using dc-dc buck converters:

- Changing modes of operation: One of the simpler methods for saving energy relates to the power device’s mode of operation. There are two main modes: pulse-width modulation (PWM) and pulse frequency modulation (PFM). During PFM, the integrated circuit switches off several parts of the circuit that are required for PWM, while still maintaining the given voltage for the output. In addition, modulating the switching frequency down helps minimize switching losses, because this loss is dominant at low output currents.

- Slowing down the switching: Another technique to reduce energy consumption is to slow down the amount of switching performed by the converter. Turning the high- and low-side MOSFETs on and off fewer times helps manage and minimize the power consumption. You can slow the switching down in two ways: fold back the device’s normal operation frequency to a lower frequency; then once in sleep mode, turn the device on to recharge the output capacitor to the desired voltage when needed.

- Fixing the output voltage: Another way to save energy is to have a fixed-output-voltage version for the switching converter. Due to reliability issues, external resistances are often limited to less than 100,000 Ω to avoid variance on the voltage output from component tolerance and drift. This means that there’s leakage current in the feedback loop, which will dissipate energy. With a fixed-output-voltage version of a regulator, you can scale the internal resistances to greater than 1 MΩ, so that the power needed for regulating the desired voltage drops dramatically. Higher resistances are attractive because this means lower leakage current and lower energy consumption.

Conclusion

As automakers add more functionality to their vehicles, there’s an associated energy cost. It’s very challenging for electronics to maintain proper operation and performance in the harsh environment of an automobile. As a designer, you’ll need to understand and consider what’s critical to make the right tradeoffs. By assessing the full functional needs of the system, how long it’s expected to remain on and not in sleep, and what tradeoffs could be made for size, cost, and performance, it’s possible to meet all of these needs with appropriate system planning as well as your energy-savings targets.

Martin Moss is Marketing Manager for Wide VIN Buck Switching Regulators at Texas Instruments.