This article is part of the TechXchange: Exploring Digital Isolator Technology

Download this article in PDF format.

Many new designs today absolutely require galvanic isolation between two or more pieces of equipment, or between two critical sections of a single product or system. If you haven’t done this before, you may want to come up to speed before proceeding. That means learning the basics of galvanic isolation, why it’s used, and becoming familiar with the ways to achieve it.

This article defines galvanic isolation, explains its benefits, and then summarizes the most common ways to implement it. And it reveals a fresh new approach to providing galvanic isolation with special ICs.

Sponsored Resources:

- Simplify your isolated current & voltage sensing designs

- High-efficiency, low-emission, analog input module reference design

- Fully integrated signal and power isolation – applications and benefits

Get to Know Galvanic Isolation

Galvanic isolation is the process of designing equipment or systems with separate power supplies so that the two don’t exchange power or interact in any way. The idea is to keep the dc power (and/or ac power) separate and independent. One electrical power system should not affect the other. At the same time, it’s usually necessary to transport monitoring signals and control data between the two in a fully isolated way.

Power isolation is achieved by keeping the two physical sections well apart. And that’s usually implemented by NOT connecting the ground connections of the two systems. This eliminates ground loops and reduces or at least minimizes any noise transference. When both high- and low-voltage subsystems are used, such physical and ground isolation also helps to protect users and service techs from shock, low-voltage circuits from high voltage, and in some cases, protects against lightning.

Examples of equipment requiring galvanic isolation include programmable logic controllers (PLCs) in factory tools and equipment, uninterruptible power supplies (UPS), motor drives, industrial robots, battery chargers, inverters, and occasionally dc-dc converters. And there’s a growing need in automotive applications.

Implementing Galvanic Isolation

A wide range of methods are used to implement galvanic isolation. Perhaps the oldest and still most effective is the transformer. It operates by allowing its two windings to transfer data, messages, and codes by way of magnetic fields between the primary and secondary windings. There’s no direct current flow between the primary and secondary windings.

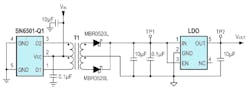

Figure 1 shows an example of a basic power supply used in a system requiring isolation. The SN6501-Q1 is an oscillator-driver that develops the switching signal for the transformer. The transformer provides the turns ratio to produce the desired output voltage and ideal isolation derived from the magnetic-only coupling between input and output. A low-dropout regulator (LDO) cleans up the rectified signal and sets the desired output voltage.

Optocouplers or optoisolators are another near ideal device for transferring data at reasonable speed. A voltage data stream drives an LED inside the optoisolator package. A phototransistor captures the light a few millimeters away. The transistor output is fully isolated from the input. Isolation is very complete.

One of the best isolation techniques is to use capacitors. They block dc but pass ac, making them and their variants extremely efficient. Other devices involved in creating galvanic isolation are special components like Hall-effect sensors and even mechanical relays.

Modern Galvanic Isolation

The best way to provide needed galvanic isolation these days is to utilize products designed particularly for that purpose. Examples include the special amplifiers and analog-to-digital converters (ADCs) used to send isolated current- and voltage-sensing data when the system needs it.

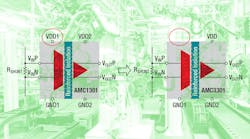

Differential amplifiers monitor the voltage across a sensing resistor to provide a current reading. Usually two power supplies are required in this application (Fig. 2, left). However, having a second supply makes the product larger, heavier, and more expensive.

Texas Instruments has developed a line of single-supply amplifiers and ADCs to overcome that issue. The AMC3301 isolated amplifier (Fig. 2, right) includes a fully integrated dc-dc converter to deliver the second supply voltage. Isolation is provided by capacitive coupling inside the IC. The AMC3301 meets the high-voltage isolation safety rules for UL 1577 certification up to 4250 V rms and DIN VDEV 0884-11 for up to 6,000 V peak.

Two types of isolation devices can be used to provide the isolated measurement and control data—an isolated amplifier and an isolated modulator. Both are single-supply types, and each contains an internal delta-sigma (ΔΣ) ADC.

The monitored analog signal is sent to the chip, amplified, and then digitized by the ADC. The ADC generates a serial bit stream that passes through an on-chip capacitive isolation barrier. This serial bit stream is subsequently sent to a low-pass filter that produces a voltage proportional to the input. At that point, the recovered dc signal may be digitized again in another ADC, perhaps one in the usual system microcontroller,

An option is an isolated modulator like TI’s AMC1305/06. It takes the current or voltage signal being monitored and amplifies it before digitizing it in a faster ΔΣ ADC. The ADC sends its signal over the internal capacitive isolation barrier to the output. This signal is a series of bits representing the voltage inside the device. An external low-pass filter generates a proportional analog signal that may again be digitized for digital signal processing.

While both isolated amplifiers and modulators do provide good performance, the isolation modulators are generally a better alternative. They have superior signal-to- noise performance, greater accuracy, and lower latency.

Galvanic Isolation 101

To assist your knowledge and understanding of galvanic isolation, you should consider TI’s TIDA-010065 reference design. The reference design is a simplified architecture for generating an isolated power supply for isolated amplifiers that measure isolated voltages and currents. On-board digital diagnostics improves reliability and enhances system performance. It’s a great self-learning platform to learn the intricacies of galvanic isolation.

Sponsored Resources: