This Week in PowerBites: PoE on Steroids, Students Hack EVs

This article is part of the Power Management Series: This Week in PowerBites

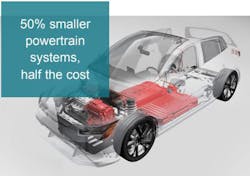

EcoCAR Design Challenge Invites Students to Help Advance EV Tech

The EcoCAR EV Challenge is accepting applications for teams of students interested in competing in the latest Advanced Vehicle Technology Competition (AVTC) series, which will kick off in the fall of 2022 and conclude in 2026. The competition is sponsored by the U.S. Department of Energy (DoE), General Motors, and MathWorks and managed by Argonne National Laboratory.

It’s the latest in a long series of clean vehicle automotive design competitions to bring together future engineers, business and communications students, and automotive leaders to accelerate the development and demonstration of technologies of interest to the DoE and the automotive industry. Applications are due January 20, 2022

Since 1988, each of the previous challenges gave students the opportunity to re-engineer a donated production vehicle. The goal is to improve energy efficiency and meet the toughest emissions standards, while maintaining the features that make it attractive to the customer: performance, consumer acceptability, safety, and cost.

The EcoCAR EV challenge will follow a similar format. This time, though, the competition will challenge up to 14 North American universities to engineer a next-generation battery electric vehicle (BEV) to implement energy-efficient and customer-pleasing features, while meeting the decarbonization needs of the automotive industry.

The four-year program will model industry-best practices with expanded focus on vehicle connectivity, simulation, and controls development to enable cooperative driving automation. EcoCAR will include a major focus on equity in mobility and Diversity, Equity & Inclusion in STEM to help foster clean energy mobility solutions and opportunities for all.

Make sure your university is part of North America’s premier collegiate automotive engineering program. Applications are due January 20, 2022

During the four-year competition, students will learn to apply their theoretical knowledge to solve not only complex engineering challenges, but also learn valuable leadership and project management skills, as well as public relations, marketing, and business development.

Participating universities will receive extensive support from competition-level sponsors to enable their success throughout the EcoCAR program. Pending final budget authorization, each selected university will receive funding for:

- Seed money for program initiation support for new and veteran AVTC universities, and for minority-serving institutions

- Graduate and undergraduate student support

- Seed money for diversity, equity, and inclusion efforts

- Cash prize money, travel support, and vehicle shipping

- A production GM BEV platform vehicle and production GM North American service parts

- Industry-leading components and hardware

- MathWorks modeling and simulation tools

- Industry mentors and subject matter experts

To learn more about the competition, and the application process, visit: https://ecocarevchallenge.org/why-apply/.

Click here to watch additional videos from previous EcoCAR Challenges.

800-V Power MOSFETs Bring Higher Efficiency, Lower Switching Losses to Lighting Apps

STMicroelectronics’ K6 series of 800V MDmesh super-junction power MOSFETs features improvements in several key parameters that enable compact, highly efficient designs for applications based on flyback topology. Such apps include LED drivers, HID lamps, adapters, as well as power supplies for flat-panel displays. Combining high performance with ease of use, the MDmesh K6 devices offer the best RDS(on) × area at 800 V currently available in the market, according to the company.

In addition, the K6 series' threshold voltage is lower than previous-generation devices, enabling a lower driving voltage for lower overall power losses. Their low total gate charge (Qg) further reduces losses and enables higher switching speeds. The MOSFETs also integrate an ESD protection diode that enables the MOSFET meet the human-body model (HBM) Class 2 specification.

The STP80N240K6 (RDS(on)max = 0.22 Ω, Qgtyp = 25.9 nC) in TO-220 through-hole package is the first MDmesh K6 MOSFET in full production, with free samples already available at the ST eSTore. The DPAK and TO-220FP versions will be in full production by January 2022. Pricing starts at $1.013 for orders of 1,000 pieces.

The complete MDmesh K6 product portfolio will be introduced by 2022, offering a wide RDS(on) range from 0.22 to 4.5 Ω and a range of package options including SMD and through-hole housings. For more information go to www.st.com/stpower-800v-mdmesh-k6.

PoE on Steroids: "Digital Electricity" Hub Uses Standard Ethernet Cable to Deliver Up to 2 kW Over Long Distances

VoltServer Inc., based in East Greenwich, R.I., has introduced its Digital Electricity technology that can safely transmit Ethernet data and up to 2 kW of power across long distances (up to 2 km) using low-cost, off-the-shelf data cables. Created to serve the growing number of applications with large numbers of remote nodes that require power and data, VoltServer's systems have been deployed in hundreds of marquee venues including stadiums, airports, convention centers, office towers, hotels, condominiums, hospitals, and indoor gardens. They power 4G, 5G, and Wi-Fi wireless communications, LED lighting, and IoT applications.

Pulsed Power Transmission

VoltServer's Digital Electricity systems are able to deliver much more power than conventional Power over Ethernet (PoE) technology because they get around the low-current capacities of lightweight data cable by using high-voltage, low-current pulses to deliver power to downstream loads. VoltServer refers to these pulses as “energy packets.” These are distributed from a transmitter containing local, embedded processing that can determine if the power is being precisely and safely distributed. If a fault is detected, the next energy packet is not sent.

Each packet contains only a very small amount of energy that’s not individually harmful to people, animals, systems, or buildings. Each end point is equipped with a receiver that converts the high-voltage pulses back into analog ac or dc to power local loads.

Plug-and-Play Power Sources

Similar to PoE, VoltServer's Digital Electricity delivery system can simultaneously send data and power over a distance up to 2,000 meters using off-the-shelf structured copper communications cable and Class 2, low-voltage wiring methods. Since this is easier and more economical to install than conventional 110/220 electrical systems, architects, designers, and facility managers can quickly and easily configure and reconfigure wireless networks, office floorplans, and agricultural grow rooms.

In addition, because the platform is natively digital, it allows users to monitor energy use with a centralized dashboard. This gives building operators and maintenance staff a granular view of their electric grid to better manage critical loads while eliminating the need for traditional circuit breaker panels.

Power-Efficient Converters Eliminate Need for Added Cooling

One of the challenges VoltServer encountered during development was the need for a compact, highly reliable bus converter that the power receivers would use to transform the higher transmission voltage to a safe low voltage to power the loads. Vicor Corp. worked closely with VoltServer to find the right ruggedized, passively cooled, BCM dc-dc fixed-ratio bus converters that are 97% efficient.

In the end, VoltServer chose the Vicor BCM6123 for use in the endpoint receiver. Not only is the converter 97% efficient, it has a very compact footprint (0.99 × 2.402 × 0.286 in.). It uses a proprietary, low-noise, high-efficiency sine amplitude converter (SAC) topology that requires little electromagnetic filtration, further shrinking the power system footprint and simplifying the design while meeting EMI standards.

The lower cooling requirements afforded by the BCM6123 allows the receivers to be placed in tight, enclosed spaces that are too small to accommodate cooling fans. The smaller heatsinks needed to cool them also enabled VoltServer to develop compact cases that can fit easily into even the most space-constrained environment.

Click here to learn more about VoltServer.

Wireless Power: Fact, Fiction, or Fraud?

Can a small wireless power startup really use its "RF Holography" technology to charge personal electronics from several meters away, without irradiating their users? Check out Lee Goldberg's in-depth follow-up article on Ossia's novel wireless power technology. It includes a video interview with the CEO, which takes a deep dive into the theory behind the technology, and another video that demonstrates it in action.

Bias-Supply Module with Integrated Transformer Helps Maximize Drive Time in EVs

The UCC14240-Q, a compact, highly accurate, 1.5-W isolated dc-dc bias-supply module developed by Texas Instruments, is intended for use in high-voltage environments such as electric vehicles (EVs), hybrid EVs, motor-drive systems, and grid-tied inverters. It features a proprietary integrated transformer technology that enables designers to cut their power solution size in half.

The module was developed to help EV/HEV designers move to the distributed power architectures required for smaller, more reliable systems that can help extend driving range. A distributed architecture, in which every isolated gate driver has a dedicated bias supply, can reduce vehicle weight and significantly improve how the system reacts to single-point failures.

Fully integrated power solutions such as the UCC14240-Q1 help engineers take advantage of distributed architecture. Learn more by reading the technical article, “Driving next-generation EV systems with a distributed architecture in a bias-supply.”

Extend Driving Range with High Power Density and System Efficiency

Able to deliver more than 1.5 W at ambient temperatures of 105°C, the UCC14240-Q1 enables engineers to drive isolated gate bipolar transistors (IGBTs) as well as silicon-carbide (SiC) and gallium-nitride (GaN) switches at high frequencies. Its 3.55-mm height and small footprint helps designers reduce the power solution volume by as much as 50%, while delivering 60% efficiency—twice that of traditional bias sources.

Achieve High CMTI, Ultra-Low EMI, and Accurate Protection

The UCC14240-Q1 features soft switching, spread-spectrum modulation, shielding, and integrated transformer technology that produces a 3.5-pF primary-to-secondary capacitance. This greatly mitigates the EMI caused by high-speed switching and achieves common-mode transient immunity (CMTI) performance of more than 150 V/ns.

The UCC14240-Q1’s integrated closed-loop control enables ±1.0% accuracy from −40 to 150°C. The device’s tight tolerance enables the use of smaller power switches while also improving overcurrent protection. Fault monitoring, overcurrent protection, overpower protection, and overtemperature protection are all fully integrated. The UCC14240-Q1 offers third-party-certified 3-kV rms isolation and delivers high vibration immunity due to its ultra-low weight and 3.55-mm height.

Packaging, Availability, and Pricing

The UCC14240-Q1 is available in pre-production quantities from TI in a 36-pin, 12.8- × -10.3- × 3.55-mm shrink small-outline package. Pricing starts at US$4.20 in 1,000-unit quantities. Engineers can evaluate this product with the UCC14240Q1EVM-052 evaluation module, available on TI.com for US$59. For more information, see ti.com/UCC14240-Q1-pr.

Compact Automotive-Grade EMI X2 Film Capacitors for Harsh Environments

KEMET recently introduced its R53 series of miniature, polypropylene film X2 EMI (electromagnetic interference) suppression capacitors. This series fulfills the growing need for automotive, industrial, consumer, and energy applications that require a smaller, high-capacitance X2 class solution for suppressing EMI.

The R53 series offers capacitance values from 0.1 to 22 µF, lead-spacing from 15 to 37.5 mm, 85/85 THB Class IIIB classification, and long-life stability in harsh environmental conditions. Its volume, on average, is 60% smaller than competitive X2 class capacitors, enabling a smaller PCB area, reduced weight, lower costs, and improved reliability. At the time of its introduction, all other available solutions comparable to the R53 series have either larger dimensions or require multiple capacitors in parallel to achieve an equivalent value.

With a rated 310 V ac at 50 or 60 Hz, this series is intended for use in Class X2 line-to-line applications or in series with the ac mains. R53 capacitors are well-suited for ac-dc converters in onboard chargers for xEVs, smart grid hardware, EMI filtering in variable-frequency drivers (VFDs), LED drivers, and high energy density applications such as capacitive power supplies.

The R53 series features a metallized polypropylene film encapsulated in a self-extinguishing resin and a shell that meets UL 94 V-0 requirements. The metallized polypropylene film combined with an internal parallel construction provides self-healing properties to prevent catastrophic failure and extend service life.

A growing number of applications require miniaturization and operation in harsh environmental conditions, including onboard chargers, smart electric meters, capacitive power supplies, as well as connection in series with the mains, motor drives, and wind and solar inverters. R53 capacitors are AEC-Q200 qualified, designed for harsh environments, and meet the highest standards of reliability required for smart-grid hardware, often located in limited-access areas where regular service isn’t available.

The R53 series is available immediately via KEMET distributors. To learn more about its capabilities and applications, visit https://ec.kemet.com/film.

Flyback Switcher ICs Simplify USB-C PD with On-Chip Controller, Isolation, and Protection

The InnoSwitch3-PD family of ICs from Power Integrations offers a highly integrated solution for USB Type-C, USB Power Delivery (PD), and USB Programmable Power Supply (PPS) adapters. The compact InSOP-24D-packaged IC integrates a USB-C and PD controller, a high-voltage PowiGaN switch, a multi-mode quasi-resonant flyback controller, secondary-side sensing, FluxLink isolated digital feedback, and a synchronous-rectification driver.

This latest addition to the InnoSwitch3 family dramatically simplifies the development and manufacturing of compact, energy-efficient USB PD power supplies for smartphones, tablets, notebooks, and other devices that benefit from fast charging. InnoSwitch3-PD ICs reduce the BOM count to half that of conventional designs.

Featuring no-load power consumption as low as 14 mW, power-supply designs using InnoSwitch3-PD ICs meet all global energy-efficiency regulations. The high efficiency of these devices ensures low heat dissipation, eliminating the need for bulky heatsinks. Power Integrations’ FluxLink high-speed communications feedback link delivers fast, accurate secondary-side regulation.

InnoSwitch3-PD ICs also are fully protected. They feature input voltage monitoring, accurate brown-in/brown-out and overvoltage protection, and output overvoltage and undervoltage fault detection with independently configurable fault responses.

Availability and Resources

A new design report, RDR-838, describes a 60-W USB PD 3.0 Power Supply with 3.3- to 21-V PPS output using the InnoSwitch3-PD PowiGaN-powered INN3879C-H801. The new InnoSwitch3-PD ICs are priced from $1.30 per unit in 10,000-unit quantities.

For additional information, visit the InnoSwitch3-PD page on Power Integrations' website. Click here to watch a short video on the InnoSwitch3-PD.

Read more from the Power Management Series: This Week in PowerBites