Members can download this article in PDF format.

Capacitive, optical, and inductive isolation technologies are design principles that have been around since the beginning of modern electronics. While devices such as capacitors and inductors serve a variety of functions within an electronic device, they, along with optoelectronics, also can be used to isolate circuits from each other.

As new applications arise and others evolve, such as factory automation, motor drives, grid infrastructure, energy, and electric vehicles (EVs), the ability to isolate circuits becomes critical due to the high-voltage components of these applications. Isolating these high-voltage circuits from the low-voltage circuits, which are oftentimes digital (e.g., voltage- and current-sensing communication and signal processing) becomes paramount. It’s also critical to ensure that users are completely isolated from those high voltages.

Sponsored Resources:

- Addressing high-voltage design challenges with reliable and affordable isolation

- AFE for insulation monitoring in high-voltage EV charging and solar energy reference design

- TI's portfolio of isolated ICs

An elegant method for accomplishing this is through galvanic isolation (GI). Galvanic isolation is an ideal method for isolating partitions. While GI isn’t new, the technology has evolved thanks to numerous advances. Each GI technology has its particular advantages and disadvantages, and the best solution depends on the application.

On that front, TI offers an array of leading-edge solutions such as the TIDA-010232 AFE reference design for insulation monitoring in high-voltage EV charging and solar energy. Products range from the TPSI2140 and TPS13050/52 solid-state relays to signal-isolating products such as gate drivers, amplifiers, comparators, interfaces, analog-to-digital converters (ADCs), and modules.

Drilling Down

The most commonly used circuit is transformer-based. The venerable is well-understood and has stood the test of time, until recently. As the digital transformation gains traction, this inductive technology starts to bump up against some limitations in the digital domain at higher frequencies. Typically, these are susceptible to stray magnetic fields and increased power consumption, but there are other issues.

A major advantage of magnetic isolation is its main component is a mechanical device—a transformer. That makes it cheap and relatively bullet-proof, and it’s well-entrenched. It offers other advantages over capacitive, too. Still, it has the disadvantages mentioned above.

Capacitive GI

Capacitor-based GI is a new paradigm for high-voltage use cases. Unlike inductive technology, capacitors can’t pass dc. Thus, they become the ideal solution for many emerging GI use cases. Capacitive solutions are insensitive to stray electromagnetic (EM) fields, can run at very high speeds, and have lower power consumption. Also crucial is that they’re much more compact, which is generally a standard requirement for circuits today.

The capacitive trend has become possible thanks to solutions from companies such as TI. Its silicon-dioxide (SiO2) process offers insulating properties with a dielectric strength of ~500 VRMS/µm, and it can be used in high-voltage applications.

This newly developed manufacturing process uses silicon dioxide, the basic on-chip insulation, for the dielectric. As a result, the isolation circuit can be integrated on-chip with the other circuitry to prevent the pass-through of high-voltage, high-frequency signaling. Furthermore, the integrated solution provides shock protection in a single package. The process and technical details are well described in their brief.

Optical GI

Optical isolation is the third methodology for GI. Optical isolators are capable of working with voltages of up to 5 kV, even more in special cases.

Optical isolators are good for many cases but come with some significant disadvantages. First, they’re low-speed devices. Such isolators also are nonlinear for most analog measurements. Response time is slow and they’re not generally recommended for high-speed applications. their specification characteristics tend to drift over time. And they’re inexpensive.

However, since many high-voltage applications have circuits that aren’t necessarily high speed, they’re still applicable to high-voltage GI use cases.

Typical Circuits

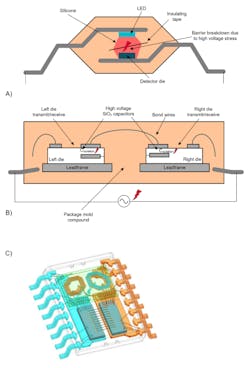

Todays advanced high-voltage isolation circuits are IC-based. Such circuits integrate the best properties of optical, capacitive, and inductive technologies. They offer outstanding dc and low-frequency ac blocking while passing the desired digital, analog, and power signal to propagate through. The figure shows a simplified diagram of each circuit type.

Applications

Perhaps one of the best GI use cases is the emerging EV market. In this space, end-user safety is of the utmost importance. And the proliferation of EVs will put a significant portion of the population at the smoking end of the power grid.

As is usually the case with consumer electronics, the user needs to be isolated from any power sources. Moreover, the interface must be as foolproof as possible.

Various approaches exist to EV charger design (a primer on these can be found here). Some are early designs that will eventually phase out, replaced by new methods that are better matched to the improvements in battery technology (faster charging, higher capacity, denser, etc.).

Another proliferating use case is the energy segment. Energy management is a high-tech process that monitors and controls many types of electrical distribution systems. Galvanic isolation is a critical component at nearly every stage of these systems. Modern power systems are based on a digitized power-distribution network. That means many low-voltage systems are integrated into the network. And to protect the digital network, GI is heavily implemented.

Another segment that relies heavily on GI is the medical field. This segment is perhaps the most demanding when it comes to patient and provider safety, which is evidenced by the heavy regulation of the FDA.

Electrical isolation is one of the main priorities for the medical equipment that’s directly connected to the bodies of patients. Such devices include defibrillators, endoscopes, ECG, EEG, and a variety of imaging devices.

The consumer arena is yet another that employs GI, particularly in communication systems. Examples include routers, Ethernet, switches, racks, and many more. Standard consumer goods like switched-mode power supplies (SMPS), chargers, logic boards of computer are the most frequent users of GI.

While some of these examples don’t necessarily use extremely high voltages, they all use household ac, which can be just as damaging and dangerous as hundreds of volts. Protecting consumer devices from high voltage has been standard for some time.

Conclusion

Galvanic isolation is both old and new. Bringing semiconductors into the mix has upped the ante by an order of magnitude, enabling many isolation methods to be implemented at the cutting edge of digital technologies.

Texas Instruments is on the forefront of these exciting developments with an array of technologies and products that bring safety and protection to myriad industries, helping them reach a new level of design, performance, and reliability.

Sponsored Resources: