The quest to replicate some of the many functions of human skin involves multiple unique approaches and forms. One of the many challenges is that skin is soft and deformable, and senses at thousands of points, so using discrete sensors and interconnecting wiring is impractical.

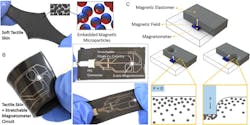

However, researchers at Carnegie Mellon University (CMU) are pursuing a very different approach to meet one of the needs of electronic skin (e-skin). They’re using a deformable, silicone-based covering that’s embedded with micro-magnetic particles. They then sense changes in the orientation of these particles via changes in the overall magnetic-field intensity and orientation, and process the data using complex, sophisticated classification algorithms to determine the nature and location of the deformation.

This soft skin is composed of silicone rubber elastomer embedded with millions of microparticles that move as the skin-like material makes contact with an object and deform (Fig. 1). The magnetic Ne-Fe-B microparticles were on the order of ≈200 μm in diameter. They used these microscale magnetic particles to reduce the intensity of internal stress concentrations when a mechanical load is applied and to retain the flexible or stretchable properties of the “skin.”

An arrangement based on a Melexis MLX90393 micropower Triaxis magnetometer with electronics on a standard SparkFun board was attached to the elastomer to sense changes in its magnetic field, which are the result of localized pressure and deformation. The magnetic skin required no electrical connection to the underlying magnetometer board; instead, it required proximity for the magnetic flux changes to be detected.

Although millions of individual magnetic particles are distributed throughout the skin contributing to the magnetic field, they measured it using a simple three-axis output that preserves information about the deformation. By implementing advanced pattern-recognition and classification algorithms on the changes in magnetometer output, the arrangement can infer the location and direction of the deformation, somewhat analogous to what real skin (and the brain) can do.

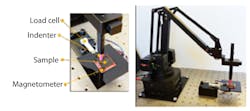

To quantitively validate this proof-of-concept sensing-skin project, they programmed a 4-degree-of-freedom (DOF) robotic arm to apply pressure of an indenter (pressure measured on a load cell) and collect data on magnetic field change (Fig. 2).

They collected this data over a 15-mm2 and 5-mm diameter circle. Using a model-based analysis (Fig. 3), they developed classification algorithms and were able to localize pressure with an accuracy of >98% to within a 3-mm2 area (on average) for both grid and circle patterns.

The CMU team is also focused on application-specific scenarios, such as “soft robotics” in medicine for gastrointestinal (GI) endoscopy. Their next objective is to enhance the ability of this “skin” to sense and localize the force and deformation when handling cylindrical objects such as catheter endoscopes. Full details, including modeling of circular and square indents, numerical analysis, and results, are in their paper “Soft Magnetic Skin for Continuous Deformation Sensing” published in Advanced Intelligent Systems. Further details of the modeling and arrangement are in their posted Supplemental Material.