Keeping many food and pharmaceutical product cold and monitoring that cold chain has always been important—a reality that’s becoming increasingly apparent given the worldwide supply chains involved (think vaccines). While RTDs can be used to sense the temperature, they have issues with power consumption, accuracy, and multi-channel performance.

Maxim Integrated’s single-channel MAX31889 high-accuracy digital temperature sensor (Fig. 1) targets general and especially “cold-chain” food and pharma product temperatures, with its ±0.25°C accuracy from −20 to +105°C, and ± 0.65°C accuracy from −40 to +125°C. It provides what Maxim maintains is the industry’s highest accuracy across a wide temperature range, along with power consumption which is just 35% that of other available solutions. The MAX31889 operates from a 1.7- to 3.6-V supply voltage and consumes just 68 µA during measurement.

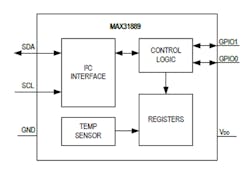

The 16-bit resolution (0.005°C) IC uses a standard I2C serial interface to communicate with a host controller. It includes a 32-word FIFO for the temperature data plus high- and low-threshold digital temperature alarms. Two GPIO pins are available—one can be set to trigger a temperature conversion, while the other can be set to generate an interrupt for selectable status bits.

The functionally related MAX31825 communicates over a 1-Wire bus that, by definition, requires only one data line (and ground) for communication with a microcontroller. In addition, the sensor can derive its power directly from the data line (so-called “parasite power”), eliminating the need for an external power supply. It supports up to 64 devices all connected to the same parasitically powered 1-Wire bus (Fig. 2). It yields 8- to 12-bit temperature measurements with better than ±1°C accuracy from 0 to +70°C, and ±1.75°C from −45 to +145°C.

Each device has a unique 64-bit serial code stored in an on-board ROM code that can be optionally programmed via an external resistor with a location address, simplifying system design and reducing design and wiring complexity. Maxim says that the 1-Wire approach improves system robustness by delivering factor-of-weight reduction in wiring compared to alternate two- or three-wire solutions.

The sensor’s IC can be powered from the data line (2.3 to 3.6 V), eliminating the need for a separate supply, or via 1.6- to 3.6-V external power; standby current is just 2.5 µA. It includes user-definable alarm settings and an alarm output for detection of temperature faults.

Evaluation boards are available at $65 each for these sensors. The MAX31889EVSYS# system consists of the MAX32630FTHR microcontroller board and MAX31889 EV kit board (Fig. 3) connected via headers. The controller board contains the firmware necessary to use the PC GUI program and provides power to the MAX31889 EV kit board.

For the MAX31825, the MAX31825EVSYS1 kit contains an on-board DS2482 I2C to 1-Wire converter (Fig. 4) and comes with the 6-pin WLP MAX31825ANT+ installed, along with Windows-compatible software.

The single-channel MAX31889 is housed in a 2- × 2- × 0.8-mm-thick 6-pin µDFN package, priced at $1.65 (1000-piece orders). The MAX31825 1-Wire temperature sensor comes in a 6-bump WLP device and is priced at $1.55 (1000 pieces).