Voltage Regulators Rev Up PWM-Based Fan Control

The simplest of fan-control schemes — an on-off switch — is simple but inefficient, because it provides more cooling than necessary most of the time. When on, the fully powered switch-controlled fan also generates a maximum amount of noise. More recently, the use of pulse-width modulation (PWM) has improved the efficiency and regulation of fan controllers, but PWM is not a perfect solution, either. However, there are two alternatives to the direct use of PWM signals for controlling the speed of 3-wire fans. One is an inexpensive “bulletproof” technique based on a linear regulator, while the other is a more efficient approach that employs a switching regulator.

Typical fan-controller ICs provide a PWM output for regulating fan speed. Normally, this low-frequency signal (~30 Hz to 100 Hz) adjusts the fan rotations per minute by cycling the fan motor on and off via an adjustable duty cycle. Unfortunately, chopping power to a 3-wire fan (power supply, ground and tachometer output) inhibits the tachometer signal that provides feedback to the fan controller, because cutting off the signal during low portions of the duty cycle affects the control loop. Some fan controllers attempt to compensate for this effect, but with limited success. The on/off cycling also can produce an objectionable clicking noise.

One solution to these problems is to smooth the PWM signal with a low-pass filter and use that voltage to control a linear driver. For a 12-V fan, the resulting control voltage is typically 5 V to 12 V, and you can use an inexpensive linear voltage regulator to drive the fan. Otherwise, such circuits introduce an RC filter for smoothing the PWM output, which is then buffered by an op amp and current-amplified by an external pass transistor. That approach is functional, but without additional protection circuitry it is subject to damage. A shorted fan can blow out the circuit.

The popular linear voltage regulator is well suited to drive a fan. It combines the op amp, pass transistor, current limiter, short-circuit protection and over-temperature protection all in one package at a reasonable price. More importantly, a typical linear-regulator IC can supply 0.5 A to 1.5 A, which covers most of today's fan-control applications.

In a typical application, the controller applies a 100-Hz PWM signal to the base of a pass transistor, which controls fan speed according to the PWM duty cycle, by toggling the fan-motor current off and on. The circuit of Fig. 1 also controls the fan with a 100-Hz PWM signal, generated by the open-drain output of U1 (the MAX6639, a 2-channel temperature monitor with dual automatic PWM fan-speed controller).

Instead of the on/off control of a pass transistor, however, the PWM signal in Fig. 1 controls the output-voltage level of a linear voltage regulator (U2). U1's PWM output is smoothed by an RC network consisting of the Thevenin equivalent of R1, R2A and R2B, multiplied by the value of C2.

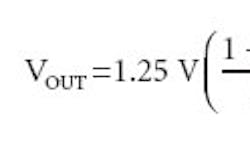

U2 regulates its output to maintain 1.25 V between the VOUT and ADJ pins. Temporarily ignoring the effect of U1, the output voltage of U2 (VOUT) is 1.25 V × (1 + R2/R1), where R2 = R2A + R2B. To account for the control influence of U1, note that R2A sets the minimum output voltage. With U1's PWM-polarity bit set for a positive duty cycle, a 0% duty cycle produces a low PWM signal that turns the open-drain output continuously on, removing R2B by placing a short across it. The R2A value shown (3.3 kΩ) then produces a minimum output of 4.7 V, which is low enough to minimize the fan's power consumption while ensuring a valid tachometer signal from the fan.

The sum of R2B and R2A sets the maximum value of VOUT. At 100% duty cycle, the open-drain output is open (off), so the full value of R2B is present in the divider network. An R2B value of 7.5 kΩ produces a maximum VOUT of 12.5 V. C1 and C4 are typical input-bypass capacitors, and C3 is U2's output capacitor, which smoothes the output voltage and supplies ac ripple current to the fan.

Trading Simplicity for Efficiency

The linear-regulator circuit described previously provides valid tachometer operation along with protection against overtemperature and short circuits, but it does so at the expense of power dissipation. For low-power fans, this extra dissipation may not be a problem, but it certainly is for large fans. Dropping 7 V or so (12 V down to 5 V) at 500 mA dissipates 3.5 W in the regulator or pass transistor. Yet, the fan's purpose is to cool other elements in the circuit, not the fan controller itself.

Now is the time, as for other power-management schemes that seek better efficiency and less power dissipation, to consider a switching regulator. Like the linear regulator above, it must smooth and level-shift the fan controller's low-frequency PWM signal. And again, the controller selected in this example is the 2-channel temperature monitor with dual-automatic PWM fan-speed control (MAX6639). As for the linear regulator, we prefer a popular part such as the LM317.

Choosing the switching regulator is harder because there are so many choices, topologies and manufacturers. However, the choices are greatly reduced in this case by the type of switcher required: it must be a stepdown type that reduces the notebook computer's battery voltage or external power source from 12 V to 5 V. It should also provide current limiting for a shorted fan, moderately high-voltage operation (25 V or higher) for direct operation when connected to a charger, integrated drive transistors and simple voltage-mode feedback. These criteria governed the choice of U2 shown in Fig. 2 (MC33063A).

U2 is configured as a classic stepdown regulator. Because the circuit makes use of its internal transistors, we must keep their peak currents below the specified limit of 1.5 A. Peak current for a stepdown configuration is IPK = 2IOUT, so we must limit IOUTMAX to less than 750 mA. R3 sets the peak current limit: R3 = 0.3 V/IPK. With R3 = 0.5 Ω as shown, the peak current limit is 600 mA, which allows the use of an inductor with lower current rating and a 1-A Schottky for recirculation diode D1.

To avoid audible noise, C1 sets the PWM oscillator frequency well into the ultrasonic region (50 kHz). That frequency provides good efficiency without imposing the need for an unreasonably large inductor. Based on the 5-V minimum output voltage, the L1 value was set at 47 µH.

The output voltage applied to the fan is VOUT = 1.25 V × (1 + R2/R1), where R1 is the parallel combination of R1A and R1B. U1's PWM output is a 100-Hz open-drain signal. At 100% duty cycle, the PWM output is a turned-off open-drain transistor, which effectively disconnects R1B from the circuit.

Fan voltage is then VOUT = 1.25 V × (1 + 3.6 kΩ/1.2 kΩ) = 5 V. At 0% duty cycle, the PWM output is effectively ground potential. R1 is then the parallel combination of R1A (1.2 kΩ) and R1B (600 Ω), or 400 Ω. The fan voltage is therefore:

In practice, the actual output voltage is slightly lower. U1's PWM output is not referenced to a true ground. Instead, it sits on a voltage produced by the output transistor's RDSON value times 2 mA (that is, the 1.25-V reference voltage at U2 pin 5, divided by R1B = 600 Ω). As explained previously, a 0% duty cycle gives 12.5 V and a 100% duty cycle gives 5 V. Normally, you would rather have the opposite (more cooling as the duty cycle increases), which is easily achieved by inverting the output polarity of the PWM signal via a configuration bit.

At intermediate duty cycles, the PWM output is smoothed by C4. A greater capacitance value will reduce ripple at the expense of response time. Therefore, 1 µF was chosen as a good compromise between response time and ripple reduction.

U2's hysteretic feedback simply shuts off the output when the pin-5 voltage exceeds 1.25 V. Because we are using a simple filter (the Thevenin-equivalent combination of R1A, R1B, and R2, times C4), the output can shut off at intermediate duty cycles, when the C4 voltage exceeds U2's reference voltage. This effect can be compensated by providing a larger-than-necessary value for the output capacitor (C2). C2 provides the “ride through” time that powers the fan during off portions of the duty cycle. To find the proper value, one must experiment because it depends on variables such as the minimum voltage for valid tachometer operation, the minimum operating duty cycle and fan-noise considerations.

A C2 value of 470 µF was selected for the fan in Fig. 2 (which draws 175 mA at 12 V), based on 1 V of output-ripple voltage at the minimum operating duty cycle (10% in this case). A larger value can be used; the only penalties are cost and size. Because most fans can easily tolerate some ripple, the main concern is to avoid reducing the fan-drive voltage to a value for which valid tachometer operation is not guaranteed, or to a level at which the fan-voltage modulation creates clicking or other undesirable fan noise.

Finally, note that the purpose of the Fig. 2 circuit was to regulate fan speed with greater efficiency than that of Fig. 1. That advantage is readily illustrated by a graph comparing efficiencies for the two circuits (Fig. 3).