Bringing Ultra-Low-Power Timing to Next-Gen IoT Devices

Timing devices supply the heartbeat for compact, wirelessly connected IoT devices that can sense, process, and communicate seamlessly with cloud and mobile platforms. These requirements place strict demands on these parts, which must come in a compact form factor and exhibit low power usage along with high accuracy. Failing to meet these requirements can take a toll on device performance, battery life, and overall reliability.

In IoT devices, timing components — including kHz and MHz crystals and oscillators — deliver highly stable reference clocks that help ensure reliable operation of the microcontrollers (MCUs) at the heart of most of them. In smartwatches and other wearables, for instance, accurate timing ensures that data is sampled and transmitted correctly, enabling precise monitoring and synchronization across the IoT ecosystem.

Precise timing also underpins robust wireless connectivity. Accurate timers play a critical role in minimizing data loss and errors as well as preventing desynchronization or signal drift, which is essential for consistent operation. They bolster connection stability and smooth out transitions between the many protocols used in IoT devices, such as Wi-Fi, Bluetooth, and Thread, while preventing data loss or link drops. Accurate timing is also vital for fast, stable reconnections during startup or wake cycles, when IoT devices must instantly rejoin the network.

However, robust timing requires careful engineering. For instance, as quartz-based resonators shrink, the equivalent series resistance (ESR) and other parameters can increase, impacting efficiency and stability. Selecting low-ESR, high-accuracy crystals with the right packaging can help balance power consumption, oscillation stability, and reliability — all of which are key factors in delivering high-performance, energy-efficient IoT designs.

Understanding Equivalent Series Resistance

Crystals are essential in electronic devices, delivering precise timing signals for applications such as microprocessors and communication systems.

The performance of the resonator is a key requirement for these systems, as it enables efficient power consumption and enhances device reliability. The device must also ensure stable oscillation and precise synchronization of operations and be small enough to support the integration of multiple functions and components within compact devices.

A key parameter influencing performance is the equivalent series resistance (ESR). ESR acts as an inherent resistance that opposes oscillation, causing part of the input energy to dissipate as heat. This loss reduces efficiency, which is particularly critical in low-power applications.

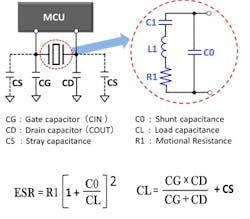

In a circuit, a crystal is represented with motional capacitance, motional inductance, motional resistance, and shunt capacitance (Fig. 1). ESR typically approximates the motional resistance, and a lower ESR value is highly desirable. Understanding ESR allows engineers to ensure reliable and efficient crystal operation.

The Tradeoffs Impacting ESR in Timing Devices

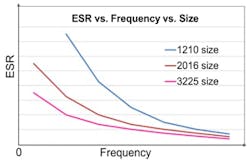

ESR is largely dependent on frequency and size. These timing devices are passive components that create a clock signal based on the vibrations of the resonator when it’s run through with electric current. Smaller crystals and those operating at lower frequencies tend to have higher ESR values. This is primarily because smaller crystals possess a higher electrical resistance per unit area, and frequencies and resistance are inversely proportional (Fig. 2).

The challenges of reducing ESR in smaller-size crystals come from inherent limitations imposed by size constraints and material properties. To achieve lower ESR values in these smaller timing devices, careful parameter optimization during the design phase is necessary to minimize resistive losses while maintaining desired electrical characteristics.

This is important because when ESR exceeds specified thresholds, issues can arise that degrade an electronic system’s functionality and reliability. Maintaining ESR within specified limits is essential to ensure efficiency, stability, and reliability; excess ESR increases energy loss, reducing efficiency and shortening battery life. By carefully selecting low-ESR crystals, engineers can wring more performance out of power-sensitive devices at the edge.

A higher ESR also means that crystals take longer to reach stable oscillation, delaying system functions, impairing performance, and increasing power even further. Moreover, the high ESR can block reliable startup, causing unstable oscillations, synchronization issues, and reduced system reliability.

How ESR Plays into Efficient Power Consumption

ESR directly impacts energy efficiency. By ensuring lower ESR, the resonator effectively reduces resistive losses during operation, leading to less power dissipated as heat. Optimizing ESR not only extends the battery life of electronic devices, but it also reduces the risk of performance degradation caused by excessive power dissipation.

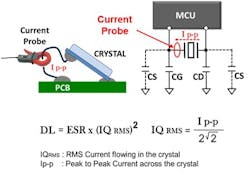

The drive level (DL) primarily affects crystal power consumption. Lower ESR reduces DL, so the crystal uses less power to maintain oscillation, thus operating more efficiently. DL can be determined from the ESR and the peak-to-peak current (I p-p) across the crystal (Fig. 3).

The Influence of Low ESR on Fast Startup Times

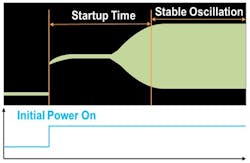

Maintaining low ESR in kHz crystals is crucial for fast startup times, ensuring a stable clock signal is provided to the microprocessor immediately after power-up (Fig. 4). Lower ESR reduces the time required for the crystal to stabilize, minimizing high current consumption during the startup period.

The startup times enabled by kHz resonators are inherently slower than in higher-frequency devices, making low ESR essential in applications that require immediate and reliable clock signals for MCUs and MPUs. As a result, minimal ESR helps enhance energy efficiency at a system level, making it a critical factor for power-sensitive electronic systems.

Low ESR Enables Stable Oscillation During Startup

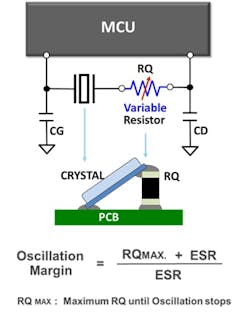

Low ESR plays a key role in determining the “oscillation margin,” which ensures stable crystal oscillation during the startup period. The oscillation margin reflects the oscillator’s ability to start and sustain reliable oscillation under varying conditions during this period.

More specifically, it’s the ratio of the oscillator’s negative resistance to ESR and can be determined by measuring the maximum series resistance (RQMAX) that the crystal can tolerate (Fig. 5). A higher margin indicates greater stability, and lower ESR improves it. RQ is adjusted until oscillation stops to determine RQMAX. A margin above 5 ensures reliable startup and stable operation.

Choosing Timing Devices to Deliver Reliability and Precision

Timing devices such as the FC1610BN that operate at 32.768 kHz can support a wide range of applications, providing designers with options to meet diverse requirements in modern portable and wearable IoT devices. A comprehensive crystal portfolio lets engineers select from a full range of packages, including industry “sweet spot” sizes, optimizing design flexibility. And the very low ESR ensures energy-efficient operation and reliable oscillation in IoT designs.

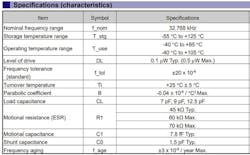

Today’s wireless IoT devices require compact size, low power, and high accuracy. The FC1610BN is a 32.768-kHz unit with ultra-low ESR that checks a lot of these boxes. The compact 1.6- × 1.0-mm package fits in space-constrained enclosures while the ESR extends battery life in energy-constrained wearables devices. The wide temperature range from −40 to +105°C ensures industrial-grade reliability in harsh conditions (see table).

Selecting the right timing device is just the first step. Design evaluation services help engineers optimize performance and reliability in their devices. Early-stage support mitigates risks such as unstable oscillation, high power consumption, or inaccurate timing, leading to reliable, energy-efficient operation and faster time-to-market.

This support can help evaluate the ESR analysis and oscillation characteristics of a design as well as the oscillation margin and startup time. Measuring frequency accuracy and drift helps to verify timing reliability for the design.

Advancing the Clock with Vertical Integration

In kHz crystals, low ESR is essential for ensuring reliable operation. It supports energy-efficient performance, fast startup times, and consistent oscillation, all of which are particularly important for portable and wearable devices. Designers can use these timing solutions to ensure precise, stable timing and maximize energy efficiency in battery-powered systems.

Understanding ESR is critical for designers, as it affects power consumption, oscillation stability, and system reliability — but it’s only part of a larger picture.

Another key factor in delivering the performance needed for IoT designs lies in working with suppliers that have a vertically integrated manufacturing process. Designing and producing both synthetic quartz crystals and semiconductor ICs in-house guarantees end-to-end control, making sure the timing solutions deliver the performance, reliability, and availability.

The vertically integrated process ensures that the timing solutions meet strict standards for uniform performance, and full control over production delivers a dependable supply chain. The integrated expertise helps in the rapid development of optimized and innovative solutions.

About the Author

Jonny Lee

Product Marketing Manager, Epson

Jonny Lee is a Product Marketing Manager at Epson. Before joining Epson, he worked in the semiconductor industry, focusing on embedded system applications. With deep expertise in quartz-based timing devices and their diverse applications, Jonny has helped customers in optimizing their system designs and selecting the best crystal products for their needs.