High-Density AC-DC Power Supply is All-In on Digital Control

What you'll learn:

- Dealing with power density through modularity.

- The value of a fully digital power supply relates to the data.

- Interpreting the data: The role of the power supply’s user interface.

A fully digital and configurable AC-DC power supply developed by XP Power, called the FLXPro series, brings improvements in power capacity and efficiency, as well as flexibility, modularity, and ease of use, to the table.

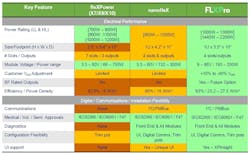

Housed in a compact 1U form factor, the FLXPro series delivers up to 1.3 kW of output power, a relatively small but significant boost over the 1.2-kW output of its previous generation. The AC-DC power supply is modular, featuring slots for up to four modules. While these modules come with different nominal output voltages, they’re also configurable so that the customer can adjust the voltage output to meet their specific needs.

XP said it made improvements across the board to increase power capacity and efficiency. Importantly, it leveraged SiC and GaN power devices to increase the power density to 23.2 W/in3.

But one of the key differentiators is its fully digital architecture, covering both the input stage and the output modules, according to Simon Wheeler, vice president of product management at XP Power. “So, you have the ability to communicate data, you have the ability to diagnose and understand what it all means, and then you can use it to control and optimize the operation of the power supply,” he told Electronic Design. “Fully digital control is important because you want to be able to do all of these things.”

Digital control is used throughout power electronics, notably in data-center power-supply units (PSUs). But XP Power is adding another dimension to it, providing deeper insights into the power supply and the system around it. FLXPro is the first series based on what Wheeler called its iPSU Intelligent Power technology, which uses data to improve system safety and efficiency while reducing operating costs. “Having the digital architecture allows you to get a deeper, richer view of what is going on inside and outside the power supply,” said Wheeler. “This is where we believe the market is heading, and we are pushing the market in this direction.”

Dealing with Power Density Through Modularity

As the demand for power density continues to rise in industrial, medical, and other high-performance systems, AC-DC converter solutions are feeling the pressure. FLXPro aims to address the challenge with a modular, flexible design.

The first product in the family is a configurable, fan-cooled AC-DC power supply called the FLX1K3 that can deliver up to 1.3 kW of power at high line and 1 kW at low line conditions. The company said these are both industry-leading in the 1U class. “That gives customers the flexibility to be able to put more power into a single complexity-reducing configurable power supply,” said Wheeler, adding that the solution fits into a compact form factor measuring 1.6 × 10 × 3.5 inches.

By using SiC MOSFETs in the power-factor-correction (PFC) stage on the input side of the power supply and SiC and GaN on the output side, XP said FLXPro runs at up to 93% efficiency, which reduces system operating costs and cooling requirements.

However, the fully digital architecture is what sets the power supply apart. The AC-DC converter input stage and the DC-DC converter output stage are both digitally controlled. “This is very unusual since most vendors will have a digital front end, but the output modules are all analog,” said Wheeler. “This is completely digital, and we use digital communications to connect each of the boards inside.” He added that it uses digital controllers to support faster control loops, enabling it to keep up with the faster switching frequencies of GaN and SiC.

One of the main features of the fully digital power supply is its flexibility. The FLXPro series supports a wide range of DC voltage outputs, including 12 V and 48 V DC. But one of its distinctive features is its ability to do voltage output adjustments. XP said the solution features up to four customer-selected, inherently flexible output modules with selectable outputs from 9 to 66 V and a wide adjustment range of +10% to −40%. They can even be configured during operation to form part of a customer’s active control system.

>>Check out this TechXchange for similar articles and videos

The problem with most configurable AC-DC power supplies, noted Wheeler, is that they are unable to handle sudden fluctuations in the voltage through the system. If the customer wants to increase the output voltage from 12- to 12.8-V output in case of voltage drop, they can rarely do anything about it themselves. He added that, in most cases, the vendor would have to modify the standard model, which is expensive and takes a lot of time.

The FLXPro series allows customers to adjust output voltage of the power supply up 10% and down 40% from the nominal voltage, meaning that they can integrate the product quickly into their application, said XP.

On top of that, Wheeler said it upgraded the power supply’s underlying topology. The LLC topology is often used by itself for the DC-DC converter stage of a modern AC-DC power supply. But the FLXPro series uses a combination of the active clamp and LLC topology to bring better efficiency and configurability. The active clamp gives it more flexibility to adjust the voltage and current outputs as needed, which is impractical with LCC alone. The LLC gives it the ability to maintain high efficiency even at very high power.

The output modules can be combined into different parallel and series configurations, and multiple FLXPro units could be placed in parallel for higher power applications. The power supply communicates with PMBus over I2C, enabling real-time control, monitoring, and diagnostics. It supports digital isolated communication, which enhances application safety while reducing integration complexity and risks of power supply damage.

Standard external connectivity is provided for output modules and the system chassis, including AC OK, DC OK, remote inhibit (global/module), fan fail/temp warning, sync, and current sharing.

The inputs, outputs, and firmware can all be configured directly over PMBus or through the user interface. That enables fast adaptation to changing application needs during design, testing, and operation out in the field, reducing both development times and system costs.

The Value of a Fully Digital Power Supply Comes Down to the Data

The digital infrastructure inside the power supply isn’t just about configurability and modularity. The FLXPro series also supports in-depth diagnostics, giving customers a deeper understanding of what’s going on both inside and outside the power supply. The system can also act as a black box, reducing troubleshooting time after shutdown events by recording in-depth system status when and before it breaks down.

“Power supply shutdowns happen all the time in development, during testing, and in operation,” said Wheeler. “So, you want a complete list of internal and external parameters of the power supply at the moment of a shutdown.”

FLXPro can record more than 50 different parameters, ranging from internal diagnostics such as the temperatures on the boards to the power, current, and voltage outputs of the power supply. When AC power is disabled, the power supply maintains its DC output for a short time and, in the interval, it stores all of the relevant information in non-volatile FRAM memory. “There are other companies that do that,” he said. “But what is different about this is that we record data starting up to three minutes before the shutdown happens.”

He added, “We are constantly recording, and so customers can see what happened leading up to the shutdown. It gives them a lot more information about not only the health of the power supply, but—more importantly—the health of the application, and this is a new concept to the market.” FLXPro can save up to four of these snapshots, enabling customers to identify trends into where, when, and how the power supply breaks down.

Additionally, tri-color LEDs on the front of the power supply indicate whether anything is wrong. “Traditionally, power supplies have had two LED indicators, one for AC OK and one for DC OK, which are either green or blank. We’re introducing tri-color LEDs: green, blue, and red. On the front of the system, we can indicate 11 different status modes of the power supply using different color combinations,” said Wheeler. A reference table is placed on top of the chassis so that customers can interpret the different indicators without referring to a manual.

In addition, internal temperature measurements enable fast status checks through extensive temperature diagnostics that drive intelligent fan control and over temperature warnings and alarms.

Interpreting the Data: The Role of the Power Supply’s User Interface

The FLXPro series is underpinned by the company’s new common user interface, called XPInsight.

Designed to be easy-to-use, XPInsight helps simplify system configuration, monitoring, and control, and it adds several advanced features such as graphing, datalogging and simultaneous multi-unit display, said XP. It helps facilitate faster decisions regarding the power supply application state, and it conveys intuitive status, health, and configuration information. “Data is useless unless you can quickly and accurately interpret it, so that is where the user interface becomes important,” said Wheeler.

By adopting a modular design, the FLXPro series can be tailored to customers whenever they need, and by simplifying setup and customization, XPInsight accelerates development timelines and reduces engineering costs, Wheeler said. With user-defined digital controls, signals, alarms and output, the FLXPro gives engineers more ability to modify the platform to meet their specific needs, ensuring optimal performance. It also offers visibility into application health, reducing maintenance and testing times as well as operating costs.

Another feature of FLXPro is secure multi-level password protection. “So, you can’t change the configuration of the power supply, update its firmware, or reset it unless you put in different passwords,” said Wheeler.

The combination of power density, modularity, and user-friendly features is well-suited for a wide range of industries, including industrial automation, medical equipment, renewable energy, test and measurement, and robotics.

Safety and reliability are central to the FLXPro series. The device is designed to meet a wide range of electromagnetic compatibility (EMC) and other safety approvals, including EN61000-4 for immunity and EN55011/EN55032 for both conducted and radiated emissions. These safety certifications ease system integration, speeding up the process of obtaining system-level approvals. It also means that a single product can cover a variety of applications, reducing design costs, said XP.

The power supply operates over a wide temperature range of −20 to +70°C.

>>Check out this TechXchange for similar articles and videos

About the Author

James Morra

Senior Editor

James Morra is the senior editor for Electronic Design, covering the semiconductor industry and new technology trends, with a focus on power electronics and power management. He also reports on the business behind electrical engineering, including the electronics supply chain. He joined Electronic Design in 2015 and is based in Chicago, Illinois.