Radical MOSFET Junction Structure Delivers Extreme Efficiency and Performance

What you'll learn:

- Details behind, and advantages of, iDEAL's asymmetric structure.

- Specs and packaging of the latest MOSFETs from iDEAL.

iDEAL Semiconductor is now sampling the first products in its new series of silicon MOSFETs that leverage its SuperQ architecture to deliver efficiencies and performance that rival some compound semiconductor devices. The first products in the new family of MOSFETs are a 150-V device with 6.4 mΩ on-resistance (RDS(on)) and a 200-V device with 6.1 mΩ RDS(on).

On an interesting and potentially important side note, technology behind the devices was developed, and is presently manufactured, in the U.S. At the time of this writing, the company is committed to continuing onshore manufacturing.

Advantages of an Asymmetrical Structure

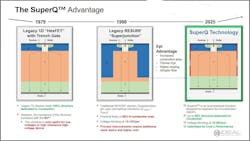

In contrast to conventional “superjunction” structures that restrict the N-conduction region to 50% of the device, iDEAL’s SuperQ MOSFETs use an asymmetrical structure that allows up to 95% of the device’s active area to function as N-conduction regions. The new architecture also dramatically reduces the amount of die real estate needed to provide voltage blocking within the device.

When combined with higher doping levels, it enables fabrication of smaller devices that exhibit voltage-blocking capabilities of 19-20V/μm and require a significantly thinner epi payer. This reduces switching losses by up to 2.1X versus competing devices. According to iDEAL, the compact transistor structures also exhibit low leakage currents, store less energy, and lower reverse recovery.

Moreover, the company claims that once in full production, the products will be very cost-competitive — the new structure requires fewer process steps and allows them to produce more chips per wafer using standard 100- to 200-mm wafers and process equipment.

While iDEAL’s present products are only rated for 150- and 200-V operation, the company said 250-, 300-, and 400-V MOSFET platforms are coming soon. This suits the products for many industrial and commercial applications involving motor drives and power conversion. However, it’s unclear yet whether the architecture will evolve to support the 800- to 2,000-V supply voltages used by most EV drivetrains. Stay tuned for details as they emerge.

The first product in iDEAL’s 150 V MOSFET series, the iS15M7R1S1C, is a 6.4-mΩ MOSFET. It’s available immediately in a 5- × 6-mm PDFN package. The SMT package includes exposed leads to simplify assembly and improve board-level reliability.

The 200-V family includes the iS20M6R1S1T, a 6.1-mΩ MOSFET in a 11.5- × 9.7-mm TOLL package. Its RDS(on) of 6.1 mΩ is 10% lower than the current industry leader and 36% lower than the next best competitor. The company is also sampling 200-V MOSFETs in TO-220, D2PAK-7L, and PDFN packages.

You can download a whitepaper that provides some additional details on iDEAL’s new architecture and the cost/performance advantages it offers.

Next in This Edition of PowerBites

More PowerBites

About the Author

Lee Goldberg

Contributing Editor

Lee Goldberg is a self-identified “Recovering Engineer,” Maker/Hacker, Green-Tech Maven, Aviator, Gadfly, and Geek Dad. He spent the first 18 years of his career helping design microprocessors, embedded systems, renewable energy applications, and the occasional interplanetary spacecraft. After trading his ‘scope and soldering iron for a keyboard and a second career as a tech journalist, he’s spent the next two decades at several print and online engineering publications.

Lee’s current focus is power electronics, especially the technologies involved with energy efficiency, energy management, and renewable energy. This dovetails with his coverage of sustainable technologies and various environmental and social issues within the engineering community that he began in 1996. Lee also covers 3D printers, open-source hardware, and other Maker/Hacker technologies.

Lee holds a BSEE in Electrical Engineering from Thomas Edison College, and participated in a colloquium on technology, society, and the environment at Goddard College’s Institute for Social Ecology. His book, “Green Electronics/Green Bottom Line - A Commonsense Guide To Environmentally Responsible Engineering and Management,” was published by Newnes Press.

Lee, his wife Catherine, and his daughter Anwyn currently reside in the outskirts of Princeton N.J., where they masquerade as a typical suburban family.

Lee also writes the regular PowerBites series.