Predictive Battery Management Extends Lithium-Ion Lifetimes

A battery-management system (BMS) depends on precise, real-time monitoring to ensure sensitive lithium-ion (Li-ion) batteries run as safely and reliably as possible, even as batteries age and loads change unpredictably. But as AI PCs and other consumer electronics add more AI and other advanced technologies, traditional BMS solutions struggle to stay on top of the fast-changing loads faced by these devices. That can lead to imprecise predictions, resulting in performance or safety issues.

To address this, Texas Instruments introduced the first battery fuel gauges based on its Dynamic Z-Track algorithm, which can adapt to rapidly changing loads and deliver more accurate forecasts of battery capacity. According to the company, the BQ41Z90 and BQ41Z50 can estimate the state of charge (SOC) and state of health (SOH) accurately to within 1%, helping boost the runtime of everything from robots and drones to power tools and e-bikes by up to 30%.

A battery fuel gauge is used to estimate SOC — the battery’s remaining energy compared to its total capacity — and SOH — the battery’s remaining lifespan compared to when it was new — by measuring voltage, current, and other metrics in real-time. They also keep tabs on resistance, which influences battery reliability, longevity, and overall performance. However, traditional methods of battery tracking are best suited for scenarios where the load remains constant or changes only slightly.

Dynamic Z-Track marks a major shift in the battery-management market, said Yevgen Barsukov, TI Fellow and Head of BMS Algorithm Development. He added that in contrast to current technologies estimating the SOC and SOH only after the conditions change, Dynamic Z-Track uses a predictive battery model that continuously updates the resistance in real-time, even under unpredictable loads. Sudden significant changes in load current can occur, for instance, when AI workloads are running in a device.

By estimating remaining capacity and remaining lifespan more accurately, TI said the new algorithm — embedded within its next-gen battery-management ICs — can maximize both metrics. As a result, engineers can adopt more appropriate batteries, reducing the need to overcompensate with oversized ones.

“Evolving from 20 years of reactive monitoring, this innovation enables users to experience dependable function, safer operation, and precise tracking of battery age and run time,” said Barsukov.

Battery Models: The Brains of High-Accuracy BMS Algorithms

With AI PCs and other battery-powered devices facing increasingly complex and fluctuating power demands, the BMS is becoming a more mission-critical component. However, building a BMS capable of monitoring conditions within each battery cell, protecting against overheating and other hazards, and extending both runtime and lifespan, poses a challenge.

There’s no one-size-fits-all BMS: Each unit must be engineered for the specific chemistry of the battery cells and the overall architecture of the pack.

Today, Li-ion batteries undergo years of rigorous testing at the cell, module, and pack levels to evaluate the electrical, electrochemical, and mechanical properties of each design. These tests involve measuring voltage, current, temperature, and other characteristics under varied conditions. Then they’re mapped to metrics such as SOC and SOH, opening a window into performance, aging, and safety. Data collected in the characterization process is used to develop a battery model, which forms the backbone of a traditional BMS algorithm.

>>Check out this TechXchange for similar articles and videos

When embedded in a system, a conventional BMS track voltages, currents, and temperatures at both the cell and pack levels and uses these models to accurately predict SOC and SOH throughout the battery’s lifecycle.

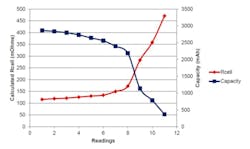

However, it's equally important to track a battery cell’s internal resistance—or impedance—to more accurately gauge the remaining charge. Measured in milliohms, internal resistance plays a critical role in determining the runtime of the battery. Lower resistance means that the battery can deliver energy more efficiently to the load. Conversely, a battery with higher resistance can supply a smaller amount of current overall, according to TI.

A battery’s impedance increases based on the number of times it’s charged and discharged. The impedance also fluctuates significantly with temperature. Impedance rises as temperature falls, which means that the battery can’t last as long before it becomes fully depleted. Tracking internal resistance is also crucial due to the capacity degradation of the battery over time, which also causes resistance to rise. These revelations into aging are crucial for calculating a battery’s remaining lifespan before it needs to be replaced.

Traditional BMS algorithms often use resistor-capacitor (RC) models of battery cells to enable accurate resistance measurements, which influence both the SOC and SOH. These models — also called equivalent circuit models (ECMs) — represent the behavior of battery cells as electrical circuits, particularly during charging and discharging cycles. They map out the internal resistance and other electrical characteristics of the battery cell by translating it into a series of resistors and capacitors.

TI said its current Impedance Track algorithm uses these models because they’re relatively compact and computationally efficient, enabling fast and accurate assessments of the battery’s performance and safety.

In most cases, though, these low-frequency models are designed to deal with slowly changing load currents. As a result, traditional battery-management ICs can struggle to capture impedance when faced with fast-changing load currents, explained Barsukov. For instance, the machine-learning models embedded in many consumer and industrial devices have unique load profiles, rising and falling from idle to full load in fractions of a second.

TI said Dynamic Z-Track solves that problem by continuously adjusting to changing impedances in the battery. While other methods of battery monitoring can falter in the face of sudden current fluctuations, Barsukov said it enables more accurate estimates of the SOC and SOH, opening the door to devices that can last longer per charge.

“With the new algorithm, we’re modeling the transient behavior of the battery,” noted Barsukov. “In that way, it becomes more generic, and it can be used in all these devices without any changes to the software.”

The predictive technology also helps simplify product development because its customers, according to Barsukov, “no longer have to keep adapting the settings for every different load, because the algorithm takes care of it by itself.”

The Hardware Behind TI’s Advanced BMS Algorithm

Unlike traditional methods of battery management that react to changing conditions in the battery, TI said its Dynamic Z-Track technology uses a more predictive approach to accurately track battery age and runtime.

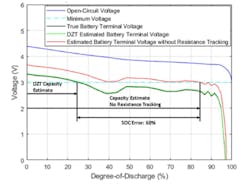

Unless the BMS can update internal resistance in real time, its accuracy tends to go down as the battery ages. Under unpredictable load conditions, errors in estimating the remaining capacity of the battery can range from 10% to as much as 60%, according to TI. For end users, these errors are experienced as a sudden drop in the reported battery life — or worse, the device can shut down prematurely due to overestimating usable capacity.

TI said Dynamic Z-Track prevents these issues. By enabling real-time resistance estimations even under fast-changing loads, it can deliver up to 99% accuracy.

“With the new algorithm, we made sure that it will always update the resistance, regardless of the load,” said Barsukov. "All the functions of the battery gauge—not only the estimation of state of charge and state of health, but also the fault detection and protection — become more reliable and easier to operate.”

To support Dynamic Z-Track, TI upgraded the underlying hardware. The BQ41Z90 is a highly integrated battery gauge, monitor, and protector that can support as many as 16 battery cells connected in series. The company said the single-chip solution enables engineers to reduce complexity, and it saves as much as 25% more PCB space compared to discrete solutions. The BQ41Z50 supports 2- to 4-cell series configurations.

To deliver deeper insights into the battery’s condition, the BQ41Z90 features a pair of high-precision analog-to-digital converters (ADCs) that have faster sampling rates for voltage and current. They can measure voltages in up to 16 battery cells and the current of the battery pack while tracking up to eight thermal measurements as well as support one internal temperature sensor. Simultaneous voltage and current sampling is supported to estimate power in real-time.

Barsukov said TI upped the overall performance of the CPU and increased the amount of on-chip memory to calculate the SOC and SOH using Dynamic Track. The chips communicate these characteristics to the system processor over SMBus or I2C.

TI said the chips can support power FETs placed in series to charge and discharge the battery pack as well as in parallel to accommodate different magnitudes of charging current versus discharging current. They integrate hardware comparators to detect overvoltage, overtemperature, overcurrent, short circuits, and other fault conditions, in addition to hardware drivers to shut down the power FETs to protect the battery from these faults.

One advantage of TI’s approach, said Barsukov, is that its battery models and algorithms are embedded in its firmware. This allows customers to manage specific cell chemistries and configurations without developing BMS software in-house.

Predictive Battery Management for AI PCs to AI Data Centers

By capturing impedance under actual load conditions, TI’s Dynamic Z-Track potentially provides a more realistic measure of a battery’s remaining capacity.

Barsukov said its new battery gauges are also a potential fit for backup battery units (BBUs) in data centers. These units deliver a constant, uninterruptible power supply during outages and protect hardware from voltage spikes, surges, and other power anomalies by filtering and conditioning the electricity entering the rack.

While BBUs can be large high-voltage battery packs located at the base of the rack, they can also be made more compact — ranging from four to 16 cells — and installed within the rack to reduce latency, said Barsukov.

The servers in AI data centers are equipped with high-performance chips such as CPUs, GPUs, and TPUs to run training and inferencing. During these computationally intense tasks, large instantaneous current changes can occur, and TI’s Dynamic Z-Track is specifically designed to handle these transient loads, added Barsukov. “This algorithm will cover the whole range of typical backup systems, even including larger batteries.”

While TI could scale up the Dynamic Z-Track technology for high-voltage batteries in electric vehicles (EVs) and renewable energy storage, he said most of its customers develop custom algorithms for those markets.

>>Check out this TechXchange for similar articles and videos

About the Author

James Morra

Senior Editor

James Morra is the senior editor for Electronic Design, covering the semiconductor industry and new technology trends, with a focus on power electronics and power management. He also reports on the business behind electrical engineering, including the electronics supply chain. He joined Electronic Design in 2015 and is based in Chicago, Illinois.