Members can download this article in PDF format.

Low cost and simplicity of control make brushed-dc motors suitable for use in automotive applications such as window lifts, sunroof controls, locks, latches, and engine valves. However, brushed-dc motor-controller design imposes several challenges, including size constraints and the ability to respond appropriately to fault conditions. In addition, you will want to pursue design-reuse strategies to reduce development time.

Sponsored Resources:

- Integrated brushed-DC solutions

- DRV8243-Q1 evaluation module

- TI's portfolio of brushed DC motor drivers

Small Integrated Package

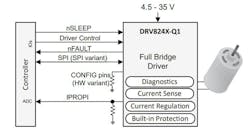

To optimize your design, start with a device such as Texas Instruments’ DRV8243-Q1 Automotive 40-V, 12-A H-bridge driver (Fig. 1). The device incorporates integrated current regulation and a current-feedback pin, eliminating the need for external current-sensing resistors, thereby reducing board space and cutting costs.

Available in an automotive HotRod quad flat no-lead package as small as 3 × 4.5 mm, the DRV8243-Q1 includes integrated field-effect transistors (FETs), further helping you save board space by eliminating the need for external FETs and gate drivers. The device is available in two interface options: the hardware (HW) version uses fixed-configuration strapping resistors, while the Serial Peripheral Interface (SPI) version provides more flexibility in configuration and observability using an external microcontroller.

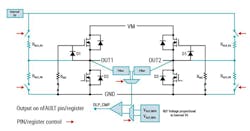

The DRV8243-Q1 includes several diagnostic and protection features to help you design a system that can handle various fault conditions. For example, it offers open-load detection and short-circuit protection in both the on and off states, using a network of passive resistors to identify system issues before enabling the FETs (Fig. 2). The SPI option provides detailed diagnostics information to help you identify the type of fault and its location, saving you time and money when troubleshooting.

All DRV8243-Q1 family members share similar firmware, features, and package pinouts to facilitate design reuse across a range of current levels and load types, including relays and solenoids as well as motors, all of which can exist within one automotive subsystem. When used in independent mode, one DRV8243-Q1 can drive two unidirectional brushed-dc motors, two solenoids, or two relays, saving space by eliminating the need for two separate half-bridge drivers.

Evaluation Module

To help you get started with designs based on the DRV8243-Q1, TI offers the DRV8243H-Q1EVM evaluation module (Fig. 3) plus software written in TI GUI Composer to control the module. You can run a cloud-based version of the software directly from a Chrome-based browser or download a version that can be installed onto your computer. In addition to the DRV8243-Q1 motor driver, the module includes an MSP430G2553 microcontroller to control the driver and an MSP430F5528 microcontroller that handles UART and JTAG communications over USB.

The module has several connectors. A micro-USB connection serves as the primary communication interface between the module and your PC, and it enables microcontroller firmware updates. A supply voltage ranging from 4.5 to 36 V dc from a battery or dc power supply connects to a screw terminal block. (The module offers fuse protection and reverse-polarity protection.)

Bidirectional brushed-dc motors connect to banana jacks labeled OUT1 and OUT2. High-side or low-side switched loads (for example, unidirectional brushed-dc motors or solenoids) can connect to banana jacks labeled Ground and VM.

Gate Drivers and Motor Drivers

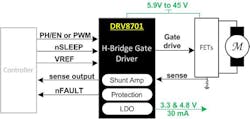

In addition to the DRV8243-Q1 40-V, 12-A H-bridge driver, TI offers a full range of other motor drivers as well as gate drivers. In the latter category, the DRV8701 47-V H-bridge smart gate driver can drive four external N-channel FETs (Fig. 4). It features integrated PWM current regulation and can limit motor inrush current.

In addition, the gate driver offers a low-power sleep mode, and it incorporates two LDO voltage regulators to power external components. Protection features include supply undervoltage lockout, charge-pump undervoltage lockout, and overcurrent protection (OCP).

Additional H-bridge motor drivers with integrated FETs include the 50-V, 4.1-A DRV8251A; the 40-V, 21-A DRV8244-Q1; and the 35-V, 3.7-A DRV8231, all of which, like the DRV8243-Q1, feature integrated current sensing and feedback. The 50-V, 4.1-A DRV8251 also has integrated current sensing and feedback but adds a latched OCP function.

All of these devices help you reduce system complexity and board size through innovative packaging and high levels of integration. Features such as low driver on-resistance (RDS(ON)) values and ultra-low sleep-current modes help you increase efficiency and extend battery life. Furthermore, accurate current sensing makes it possible to achieve precise position and torque control. Finally, integrated protection features deliver robust protection for your motor systems and intelligently diagnose fault conditions.

Technical Resources

TI offers many resources to help ensure design success. The TI Precision Labs comprehensive online classroom, for example, offers a variety of sessions, beginning with an introduction to its complete motor-driver curriculum. The curriculum includes a class that describes brushed dc-motor construction, explains how mechanical commutation works, and reviews how brushed-dc motors compare with stepper motors and brushless-dc motors.

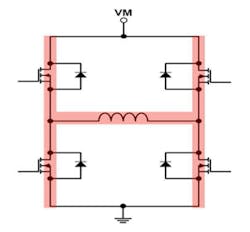

Another session describes the H-bridge circuit, which gets its name from its resemblance to the letter H (Fig. 5). The session’s instructor explains how the H-bridge can control the flow of current to a load and drive a motor in either direction. He notes that NMOS FETs are often used for the switches because, for a given size, they have a lower RDS(ON) value compared with PMOS FETs. However, NMOS FETs require a higher gate-drive voltage.

Still other sessions cover topics ranging from the significance of back electromotive force to the use of pulse-width modulation, providing a complete overview of brushed-dc-motor control.

Conclusion

System size, diagnostic and protection features, and design reusability are key factors to keep in mind when choosing motor drivers. TI offers a complete line of motor-driver products to optimize your application, and the company’s evaluation modules and full technical support help you meet design goals quickly and accurately.

Sponsored Resources: