Mastering Motor Control in 48-V EV Thermal-Management Systems

What you'll learn:

- How to develop a successful 48-V xEV thermal-management gameplan.

- Factors influencing 48V xEV thermal design: voltage transients, space-constrained design considerations, and reliability in harsh operating environments.

- Best practices for 48-V thermal-management component selection.

As electrification reshapes the transportation industry, the use of smaller, denser, and more efficient electronic and electrical (E/E) assemblies is intensifying the need to manage heat stemming from higher power levels. A key contributor to this trend is the move from 12-V supply rails to 48-V systems. But this change is also transforming thermal strategies across the electric and hybrid electric vehicle (xEV) landscape.

Growing energy requirements, combined with the opportunity — and industry pressure — to reduce wiring weight and increase vehicle range and operating efficiency, are accelerating the use of higher-voltage power networks. This includes hybrid EVs that are adopting 48-V electrical systems to support active suspension, electric turbocharging, and an expanding set of pumps and blowers for battery, engine, and cabin cooling.

These new designs can handle loads too large for traditional 12-V systems. And they don’t have the complexity and safety measures required by high-voltage main traction systems — in many cases, 400 V or above — prevalent in all-electric cars.

Why 48-V Power Hits the Automotive Sweet Spot

The basic principle behind the shift to the 48-V DC bus is simple: power (P) = voltage (V) × current (I). Quadrupling the voltage from 12 V makes possible the delivery of the same power level for significantly less current — an option welcomed by Tier 1 engineers and automotive OEMs alike (Fig. 1). By reducing the amount of current needed by the wiring to supply the car’s high-power subsystems, 48 V enables the use of lighter, thinner wires that weigh less — and cost significantly less, too.

In addition to the weight and cost savings, switching to a 48-V power system can dramatically reduce the I2R losses that occur as power pushes through wiring. That potentially means less heat and, thus, more efficient thermal management.

While voltages above 48 V could deliver additional power savings, they come with tradeoffs. Beyond 60 V DC, OSHA guidelines and industry standards such as IEC 60950 and ISO 6469 impose protective requirements that add cost and complexity to product design and certification. On top of that, components rated for higher voltages, such as capacitors, MOSFETs, and connectors, are typically more expensive, more difficult to source, and can be more challenging to integrate into space-constrained environments.

At high voltages and switching frequencies, engineers also face more pronounced electromagnetic interference (EMI) and reliability concerns. For the foreseeable future, this lands 48 V in the sweet spot: high enough for substantial efficiency gains, but low enough to avoid the complexities of full high-voltage design.

>>Download the PDF of this article

48 V Can Indirectly Create New Thermal-Management Challenges

Despite their efficiency advantages, 48-V systems come with a unique set of issues that can actually complicate xEV thermal design. The top three that engineers typically encounter are managing voltage transients, size constraints and robustness, and boundary conditions.

1. Surviving Voltage Transients

Despite its nominal voltage, a 48-V bus operating under real-world conditions must tolerate much higher voltages due to transients. Load dumps, inductive kickbacks, and other power anomalies can push voltage levels above 70 V.

International automotive standards like ISO 21780 and Europe’s LV 148 regulations acknowledge this by requiring robust transient handling. When designing-in motor-control ICs, for example, automotive engineers are advised to source high-voltage MOSFET drivers rated up to 90 V to ensure that they provide enough headroom to safely absorb transients without damaging the system. These ICs also need to survive negative transients that occur when driving inductive loads, such as electric motors.

2. The Need for Compactness

Electronic control units (ECUs) for cooling fans and pumps need to be compact and adaptable to different vehicles. Each may have different form factors and space requirements, necessitating flexible hardware and software solutions.

Moreover, the ability to manage thermal controls, perform over-the-air (OTA) updates, and provision ample storage capacity for diagnostics and data logging requires a highly integrated and programmable solution with large amounts of on-board flash memory.

3. Reliability in Harsh Conditions

Battery cooling systems must operate reliably under harsh conditions that include extreme temperature swings, dust, and vibration. It needs a comprehensive set of diagnostics and protection features for monitoring key voltage levels and overcurrent in addition to a thermal shutdown function. In the example of an engine cooling fan, the ECU must start smoothly and maintain blower operation even when faced with obstructed airflow or other boundary conditions.

This requires analog-to-digital converters (ADCs) that enable precise sensing of load changes and system parameters to allow the ECU to detect airflow blockages or other anomalies and adjust blower operation accordingly.

Establishing a Thermal-Management Gameplan

A successful thermal-management gameplan attacks the problem from two sides by actively removing heat and passively reducing the thermal load. It’s achieved by using intelligent fans and pumps for active cooling, while maximizing system efficiency reduces the heat that must be managed in the first place.

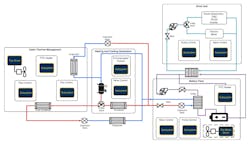

In xEVs, this strategy is applied to maintain optimal temperatures across the high-voltage battery, drive unit, and the passenger cabin, which directly impacts the xEV’s range, battery health, and passenger comfort. These subsystems rely on a variety of power electronic modules to precisely control different fluids.

Pumps circulate liquid coolants like water and oil for the battery and drive unit, while compressors manage refrigerant for the cabin’s heat pump. Smart valves, often informed by high-resolution magnetic position sensors, provide the positional control needed to track the flow of these fluids throughout the system and do so accurately.

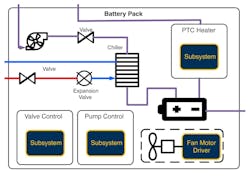

High-voltage batteries must operate within a narrow temperature range (typically between 20 and 40°C) to prevent thermal runaway, which can cause battery fires or explosions (Fig. 2). This also helps to mitigate performance degradation, extend battery life, and maximize charging efficiency for systems requiring pumps and fans.

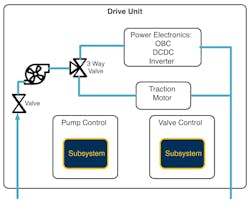

The drive unit includes power electronics and electric motors (Fig. 3). Power electronics are increasingly adopting gallium-nitride (GaN) or silicon-carbide (SiC) power FETs for their higher operating efficiency, but they still require comprehensive thermal management to ensure an optimal temperature range.

For its part, the electric motor requires a liquid (typically oil) cooling system, while recycling waste heat from electronics and motors serving the cabin and battery is crucial to extending vehicle range.

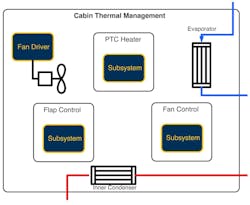

Thermal management in xEV passenger cabins directly impacts range (Fig. 4). Heat pumps improve efficiency by moving heat instead of generating it — warming or cooling the cabin or battery. These dual-mode systems replace separate heaters and A/C units, reducing energy use, weight, and cost. Controlling the electric A/C compressor is a key motor-control challenge in these systems.

How to Choose the Best Components for 48-V Thermal Management

To ensure dependable thermal management at 48 V, engineers should look for E/E solutions that combine electrical resilience, sensing accuracy, and a high level of integration. Key features to look for include:

- Wide operating voltage range (5.5–90 V) to ensure tolerance to transients and compatibility across both 12- and 48-V architectures.

- Integrated protection and diagnostics covering critical parameters like over/undervoltage, overtemperature, and bridge faults to improve system robustness.

- Advanced sensorless motor-control algorithms such as high-frequency injection (HFI) to eliminate external position sensors, which reduces BOM cost and increases system reliability.

- A complete signal-chain approach that features intelligent motor drivers with integrated gate drivers. These act as the crucial link translating a controller's commands into high-power reality, with features such as programmable slew rates allowing engineers to precisely balance efficiency against EMI performance.

- Integrated magnetic current sensors that provide a galvanically isolated way to measure current with ultra-low insertion loss. Unlike traditional shunt resistors that add significant ohmic losses and thermal-management challenges, these compact solutions provide accurate feedback needed for advanced motor control while simplifying system design and packaging.

These features help engineers build compact, robust, software-defined, thermal-management modules with the responsiveness and efficiency required by next-generation xEVs.

Develop a Thermal-Management Strategy to Optimize 48-V Performance

As power demands grow and systems become more compact and electrified, 48-V architectures deliver clear advantages in efficiency, wiring simplification, and thermal control. Yet with these benefits come new design challenges, particularly in thermal management, where even small missteps can lead to reduced performance or catastrophic system failure.

Whether controlling a blower fan or managing an xEV battery active cooling system, the challenges at 48 V are remarkably similar: transient protection, power density, real-time monitoring, and reliability under load.

Meeting these challenges requires a system-level approach with purpose-built solutions designed to work together. By selecting components from a cohesive portfolio, from high-voltage gate drivers and motor-control ICs to the current and position sensors that inform them, engineers can build robust, efficient thermal systems.

This strategy of leveraging scalable platforms simplifies development and promotes software reuse. It also ensures the full promise of 48-V power can be realized, accelerating charging times and extending driving range for the next generation of xEVs.

>>Download the PDF of this article

About the Author

Christoph Stangl

Product Marketing Manager, Allegro Microsystems

Christoph Stangl is the product marketing manager for motor drivers at Allegro Microsystems. He joined the company in February 2025, bringing over 15 years of experience in the semiconductor and electronics industry. Before Allegro, he spent more than a decade at SCHOTT AG in the Electronic Packaging business unit, where he led product management and business development, focusing on semiconductor packaging for harsh environments.

Christoph began his career at Texas Instruments in roles spanning system engineering, sales, and business development, including as a business development manager for motor control systems. His expertise lies at the intersection of technology, product strategy, and market development.