ADC Puts It All Together for Isolated Current Sensing

What you'll learn:

- The importance of voltage drop in current sensing.

- High-accuracy current sensing hinges on the ADC.

- Specs and other features of the new isolated ADC.

Current sensing is critical for enabling overload protection, monitoring loads, and regulating the performance in motors. With accurate current sensing, the motor controller can manage the motor’s speed, torque, and other characteristics, respond to changing conditions, and ensure its longevity and efficiency.

Sensing the current to each motor phase is pivotal in servo and motor drives for robotics, ranging from pick-and-place to surgical robots. It’s also a standard requirement in the humanoid robots targeted by NVIDIA’s Jetson Thor.

However, current sensing tends to come with the need for galvanic isolation, primarily for protecting against short circuits (including to nearby AC lines) and other safety hazards. Robust isolation is also important for preventing other issues such as unavoidable common-mode voltage differences between sensing side and processor side.

In most cases, you can use a current-sense resistor, signal-conditioning components, and an analog-to-digital converter (ADC) with a serial output and then isolate the output using one of several types of isolation. These can include optocouplers (optical), digital isolators (capacitive), or transformers. This works, but it requires lots of components that can crowd the circuit board. In addition, layout specifics are critical to maintain the low-level signal integrity.

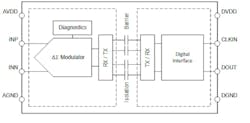

To address this problem, Texas Instruments introduced the AMC0106M25, a high-precision, isolated delta-sigma modulator that can serve as the heart of the ADC sensing current in high-efficiency motors and servo drives (Fig. 1).

The isolation barrier inside the device separates parts of the system that operate on different common-mode voltage levels. It supports a working voltage up to 200 V RMS/280 V DC and transient voltages up to 570 V RMS/800 V DC.

High or Low: The Importance of Voltage Drop in Current Sensing

Current sensing comes with tradeoffs: On one hand, it’s preferable to have a lower voltage drop across the resistor for less impact on the load current and less dissipation; on the other hand, a larger voltage drop is desirable for improved signal-to-noise ratio (SNR) and enhanced resolution. Many designers start with 100 to 200 mV as the nominal voltage range and then work down — or up — from there to find the best fit for their system’s requirements.

The AMC0106M25 features a ±250-mV input-voltage range. The part joins its similar predecessor, the AMC0106M05, which comes with a ±50-mV input-voltage range.

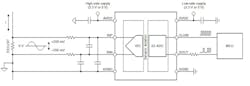

The modulator’s output is synchronized to an external clock. When combined with an oversampling ratio 256 filter, the device achieves 16 bits of resolution with a dynamic range of 88 dB and a data rate of 78 ksamples/s (kSPS) (Fig. 2).

While the new device is focused primarily on 48-V motor drives, it can also be used in 48-V power inverters as well as analog input modules and power supplies.

Why 48 V? Among the reasons:

- 48-V motors are a good fit for battery-operated, portable, mobile robots.

- The voltage is below the regulatory human-safety threshold (typically 60 V, depending on application and locale) above which much stricter regulations on spacing, interlocks, and levels of user protection are invoked.

High-Accuracy Current Sensing Hinges on the ADC

The device features low DC errors, which are important factors for accurate measurement of the millivolt levels across the sense resistor:

- Offset error: ±200 μV (max)

- Offset drift: ±2 μV/°C (max)

- Gain error: ±0.2% (max)

- Gain drift: ±30 ppm/°C (max)

The datasheet contains all of the usual specifics for a part with a heavy analog focus, including switching characteristics and timing diagrams across a range of operating conditions and temperatures. The documentation also identifies the inevitable subtleties when using a mixed-signal component such as this one, and it offers additional application and design-in details.

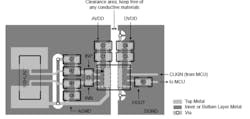

It also shows the suggested layout on the circuit board, which is one of the most important factors to maintaining isolation, along with the critical placement of the decoupling capacitors (Fig. 3).

TI has also rolled out several application notes that dig into the details of its operation and use (see References). The AMC0106M25 is housed in a 3.5- × 2.7-mm, 8-pin package and is specified over the extended industrial temperature range of –40 to +125°C.

References

High Resolution, Small Form Factor Phase Current Sense for 48V Robotics and Servo Drives (SBAA666)

How advanced current and voltage sensing enable ultra-precise robotics (SSZTD76)

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.