Know Your Safety Application Notes (Part 3): Pin FMEA

What you'll learn:

- What does a pin FMEA entail?

- Availability of FMEA information in ADI safety application notes.

- Reaching functional-safety compliance with different standards.

Part 3 is the last part in this article series discussing how Analog Devices’ safety application notes provide critical information needed for technical safety analysis by system integrators designing safety-related systems (SRS). Part 1 showed how such application notes contain an IC’s failure rate based on Arrhenius high temperature operating life (HTOL), SN 29500, and IEC 62380. Part 2 revealed how relevant failure modes can be captured in a failure-mode distribution (FMD).

This final part offers insights into an IC’s pin failure mode and effects analysis (FMEA) when designing a safety-related system. It also gets into how such pin FMEA information is available in ADI’s safety application notes.

What is a Pin FMEA?

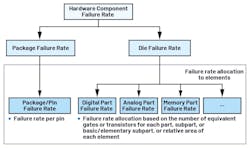

A pin FMEA focuses on the analysis of potential failure modes of an IC package and their effects on the system function. This can be used along with the package failure rate calculated, for example, via IEC 62380, to determine the failure-rate distribution of the IC. This can be seen in Figure 1.

The failure-rate allocation can then be classified into either safe, dangerous, no-effect, or no-part. Such failure-rate identification is essential to derive the safe failure fraction (SFF) and the probability of dangerous failure of the SRS.

>>Download the PDF of this article, and check out Parts 1 and 2 of this three-part series

This IC’s pin FMEA is another piece of safety information already provided by ADI’s safety application notes to help system integrators in their technical safety analysis. Figure 2 shows the pin FMEA of the LTC2933, which can be found in its safety application note. With such an application note, one will know whether a pin fault will cause damage or just operational issues to the system.

What Does IEC 61508 Say?

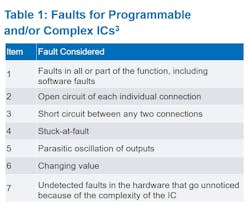

Table A.1 of the basic functional-safety (FS) standard2 shows the failures to be assumed when quantifying the effect of random hardware failures or to be considered to derive the SFF. Notably, to assume the DC fault model, failure modes such as stuck-at faults, stuck-open, open or high-impedance outputs, short circuits between signal lines, and for ICs, short circuits between any two connections (pins), need to be considered.

A pin FMEA shows these assumed failures: stuck-at faults (short-to-supply and short-to-ground), open or high impedance, and short circuit between any two adjacent connections (short-to-adjacent pin).

What Do Other Standards Say?

Compliance with functional safety often requires compliance with more than one standard. Aside from IEC 61508, system integrators designing an SRS also comply with other standards applicable to them. This may be due to national law, national directive, or sector-specific, product-specific, or application-specific standard. Often, standards have their own set of normative (required) and informative (not required) sections.

An example of an informative requirement found in ISO 13849-2 Annex D regards the failures to be assumed for different components. Table 1 shows this, indicating the assumed failures for programmable and/or complex ICs, while nonprogrammable or noncomplex ICs don’t consider the first and last assumed failures. System integrators can utilize this if they’re the ones doing the analysis for the IC to derive the FMD.

Otherwise, they can utilize what’s provided by the component manufacturer, such as in ADI’s safety application notes, as discussed in Parts 1 and 2 of this series.

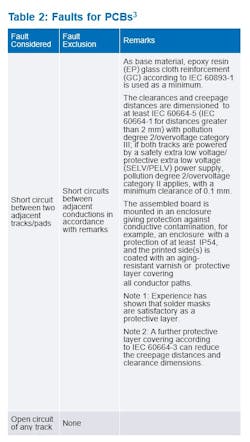

Printed circuit boards (PCBs) are also included in the technical safety analysis. ISO 13849-2:2012 has recommended fault (failure modes) and fault exclusions for PCBs wherein recommended assumed failure modes are allowed to be excluded if certain design considerations were made — for instance, those found in the Remarks column in Table 2.

With these assumed failures for PCBs, especially with the components mounted to them, system integrators will need information on the effect of such PCB failures on the IC operation, which may affect the safety function.

Note that short circuits between two adjacent tracks/pads can manifest as a form of short circuit between a pin and the supply, a pin and ground, and neighboring pins. Meanwhile, open tracks can translate to an open circuit for an IC. All of this is considered in the pin FMEA found in ADI’s safety application notes, which is readily accessible for system integrators in an FS-enabled part’s webpage.

Conclusion

This series has primarily provided guidance regarding the use of information embedded in ADI’s safety application notes. The first two parts discussed failure rates and failure-mode distributions. This final part discussed pin FMEA in the context of the IEC 61508 and ISO 13849.

Furthermore, this series raises awareness on such application notes’ existence with ADI components, especially those tagged as FS-enabled parts — standard ICs that, despite not being developed to a functional-safety standard, can still be used in safety-critical applications.

References

1. “ISO 26262. Road Vehicles—Functional Safety, Part 11: Guidelines on Application of ISO 26262 to Semiconductors.” International Organization for Standardization, 2018.

2. “IEC 61508. All Parts. Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems.” International Electrotechnical Commission, 2010.

3. “ISO 13849. Safety of Machinery—Safety-Related Parts of Control Systems, Part 2: Validation.” International Organization for Standardization, 2012.

>>Download the PDF of this article, and check out Parts 1 and 2 of this three-part series

About the Author

Bryan Angelo Borres

Senior Power Applications Engineer, Analog Devices Inc.

Bryan Angelo Borres is a TÜV-certified functional-safety engineer who currently works on several industrial functional-safety projects. As a senior power applications engineer, he helps system integrators design functionally safe power architectures that comply to industrial functional-safety standards such as the IEC 61508. Recently, he became a member of the IEC National Committee of the Philippines to IEC TC65/SC65A and IEEE Functional Safety Standards Committee. Bryan has a postgraduate diploma in power electronics and around seven years of extensive experience in designing efficient and robust power electronics systems.