Swing Aboard the 800-V Bus: NVIDIA’s AI Power Architecture and the Chips to Drive It

What you'll learn:

- Power-conversion equipment makers and power semiconductor manufacturers are racing to embrace NVIDIA’s recently announced 800-V DC AI power architecture for data centers.

- The new architecture promises improved efficiency and reduced cooling loads, as well as lower equipment and installation costs.

- To help you get ahead of this transition, we’ve curated a series of white papers that provide insight on the new architecture and the products supporting it.

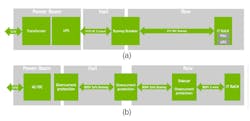

Semiconductor makers are scrambling to support the 800-V DC power architecture announced by NVIDIA for next-generation AI factory computing platforms (Fig. 1a). It was created to efficiently support the megawatt-level power consumption of the next generation’s AI server racks. The new architecture replaces the present chain of intermediate conversions needed to convert 13.8 V AC into a 54-V DC power rail with a single step that produces the 800 V DC fed to each rack (Fig. 1b).

Even ignoring the fact that NVIDIA is the “big dog” on the AI scene so it can dictate how its chips are fed, the advantages in terms of efficiency, space, and system cost are so compelling that the move to 800 V is rapidly gaining momentum.

Most major semiconductor makers, including Analog Devices, Infineon, Innoscience, MPS, Navitas, onsemi, Renesas, ROHM, STMicroelectronics, and Texas Instruments, have announced plans to support the new power architecture. In addition, power-system component makers Delta, Flex Power, Lead Wealth, LiteOn, and Megmeet, as well as data center power-system suppliers like Eaton, Schneider Electric, and Vertiv, are already on board.

With the transition in its early stages, many manufacturers are issuing informative white papers about the new power architecture, and how they will be supporting it. We’ve curated a short reading list for engineers and other tech professionals involved with the care and feeding of data centers.

To get started, you can read NVIDIA’s whitepaper on the architecture. It provides a good overview of the problems with present-day data center power systems, which led to NVIDIA’s new standard, and some of the advantages the architecture offers.

Once you’ve digested that, you’ll be ready to take a deeper dive into the practical aspects of the design, care, and feeding of tomorrow’s AI data center power systems with these informative articles:

EPC

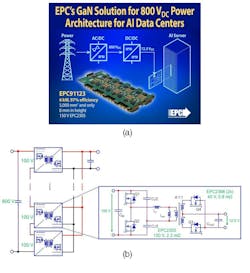

Efficient Power Conversion (EPC) jumped into the 800-V DC race with both feet by offering a high-efficiency, low-cost, low-profile, 6-kW 800- to 12.5-V converter based on its enhancement-mode gallium-nitride (eGaN) power-management FETs and integrated circuits (Fig. 2). The company’s white paper explores how the distributed architecture enabled by the converter reduces energy loss and system cost by eliminating unnecessary conversion stages and delivering power directly at the board.

You can access EPC’s white paper here: “Low Cost and Low Profile 800 VDC to 12.5 V DC-DC Converter Using Low Voltage GaN in an ISOP Topology”

Navitas

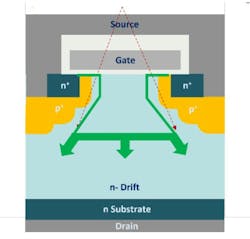

Navitas Semiconductor is also very active in supporting NVIDIA’s next-gen power architecture. As part of these efforts, the company published an informative white paper (link below). In addition to the usual background, it provides a more granular view of the various elements of the 800-V DC power architecture before it discusses the advantages of Navitas’ GeneSiC SiC MOSFET trench-assisted planar structure, which suits them for these applications.

The paper takes a deep dive into the structure of the trench-assisted GaNFET transistors, and how its proprietary architecture provides the higher power densities and performance (RON,SP , QGD × RON, and BVDSS2/RON,SP) values of conventional TrenchFETs, while its simplified architecture improves yield and production costs (Fig. 3). It also looks at Navitas’ new SiCPaK power modules, which are engineered to withstand high-humidity and high-temperature environments.

Navitas’ whitepaper is available at the following link: “Redefining Data Center Power: GaN and SiC Technologies for Next-Gen 800 VDC Infrastructure”

Power Integrations

Power Integrations recently published a white paper, which was presented at the 2025 OCP Global Summit, titled “1250 V / 1700 V PowiGaN for 800 VDC AI Data Center Architecture.” In addition to an update on the 800-V DC architecture, the paper details the performance advantages of Power Integrations’ 1,250-V PowiGaN HEMTs, with a focus on the company's field-proven reliability and ability to meet the new architecture’s power-density and efficiency requirements (>98%).

Further, the paper demonstrates that a single 1,250-V PowiGaN switch delivers greater power density and efficiency compared to stacked 650-V GaN FETs and competing 1,200-V SiC devices.

The white paper also highlights the company’s InnoMux 2-EP ICs as a solution for auxiliary power supplies in 800-V DC data centers. The InnoMux-2 device’s integrated 1,700-V PowiGaN switch supports 1,000-V DC input voltage, while its SR ZVS operation provides greater than 90.3% of 1- V system efficiency in a liquid-cooled, fanless, 800-V DC architecture.

Renesas

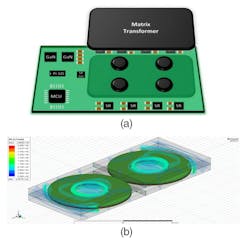

Renesas published a white paper that discusses the advantages its devices offer for 800-V power-distribution networks in AI data centers. It explores how the company’s unique power-converter architecture and other GaN power devices will enable the development of 800-V direct current buses within racks. This will significantly reduce distribution losses and the need for large busbars, while still supporting reuse of 48-V components via DC-DC step-down converters.

Based on the company’s unique LLC Direct Current Transformer (LLC DCX) topology, these converters achieve up to 98% efficiency (Fig. 4). For the AC-DC front end, Renesas uses bidirectional GaN switches to simplify rectifier designs and increase power density. Its REXFET MOSFETs, drivers, and controllers complement the BOM of the new DC-DC converters.

Click here to access the white paper, or visit renesas.com/power for additional details.

ROHM Semiconductor

ROHM Semiconductor’s recently published white paper outlines several power strategies for providing large-scale 800-V DC power distribution across AI infrastructures and details advanced power solutions that support them. The paper features the company’s comprehensive power solutions. Among them are the EcoSiC series, which offers industry-leading low on-resistance and top-side cooling modules for AI servers, and the EcoGaN series that combines GaN performance with proprietary analog IC technologies.

All of ROHM’s devices are supported by thermal design simulations, board-level design strategies, and real-world implementation examples.

Next in This Edition of PowerBites

More PowerBites

About the Author

Lee Goldberg

Contributing Editor

Lee Goldberg is a self-identified “Recovering Engineer,” Maker/Hacker, Green-Tech Maven, Aviator, Gadfly, and Geek Dad. He spent the first 18 years of his career helping design microprocessors, embedded systems, renewable energy applications, and the occasional interplanetary spacecraft. After trading his ‘scope and soldering iron for a keyboard and a second career as a tech journalist, he’s spent the next two decades at several print and online engineering publications.

Lee’s current focus is power electronics, especially the technologies involved with energy efficiency, energy management, and renewable energy. This dovetails with his coverage of sustainable technologies and various environmental and social issues within the engineering community that he began in 1996. Lee also covers 3D printers, open-source hardware, and other Maker/Hacker technologies.

Lee holds a BSEE in Electrical Engineering from Thomas Edison College, and participated in a colloquium on technology, society, and the environment at Goddard College’s Institute for Social Ecology. His book, “Green Electronics/Green Bottom Line - A Commonsense Guide To Environmentally Responsible Engineering and Management,” was published by Newnes Press.

Lee, his wife Catherine, and his daughter Anwyn currently reside in the outskirts of Princeton N.J., where they masquerade as a typical suburban family.

Lee also writes the regular PowerBites series.