Differences in Protection: Power over Ethernet vs. Power over Data Line

What you'll learn:

- The evolution of today’s Power over Ethernet (PoE) and Power over Data Line (PoDL) systems.

- The fundamental power delivery characteristics of PoE and PoDL and how these digitally integrated, power-away approaches differ.

- The unique demands and protection mechanisms that enable PoE and PoDL to support solutions across automotive, industrial, and other Ethernet-based systems.

If you’re designing anything with Power over Ethernet (PoE) or Power over Data Line (PoDL), these systems can be directly tied back to plain old telephone service (POTS) technology. While multiple innovations have sprung up between POTS and PoE/PoDL systems, POTS was the landline service used for “home phones” from the late 19th to the late 20th century. Since many engineers haven’t thought of POTS for a some time, it pays to take a look back to understand why circuit protection remains a high priority in PoE and PoDL designs.

In a way, POTS could be considered one of the first systems to power devices not using traditional AC mains. For a quick history lesson on POTS, the phone line utilized a pair of conductors, known as the “tip and ring,” that were commonly held at −48 V DC between the two conductors.

The −48 V DC that existed on the phone line was introduced to prevent corrosion of the copper line that ran between the central office (CO) and the subscriber and support telephony functions. Superimposed on this −48 V DC was a “high” frequency AC voice signal between two subscribers. Or, in layman’s terms, a telephone call between two friends.

Just as POTS delivered both power and communication over a single pair of wires, PoE and PoDL extend that concept into the digital age. PoE enables network cables to carry both data and electrical power to devices such as IP cameras, wireless access points, and VoIP phones, eliminating the need for separate power supplies.

PoDL, on the other hand, takes a similar approach, but it’s designed for automotive and industrial applications that use single-pair Ethernet (SPE). PoDL delivers power and high-speed data over just one twisted pair, making it ideal for compact, power-sensitive environments.

But with the convenience of delivering both power and data over the same physical medium comes a critical engineering challenge: protection. Just as early telephone systems had to account for issues like lightning strikes, line faults, and signal integrity, modern PoE and PoDL systems must include components that safeguard sensitive electronics from potential electrical hazards.

These hazards range from surge events and electrostatic discharge (ESD) to overcurrent situations — any of which can damage connected devices or disrupt data communication. In environments where reliability is non-negotiable, such as industrial automation, automotive networks, or security infrastructure, robust protection mechanisms are essential.

Designing effective protection for PoE and PoDL involves a careful balance. Protection components must shield against electrical faults without introducing noise or impedance that could interfere with high-speed data transmission. From power sourcing equipment (PSE) to powered devices (PDs), implementing proper safety measures is vital to ensure long-term system integrity.

>>Download the PDF of this article

Let’s explore the key protection strategies and components used in PoE and PoDL systems — and why getting them right is just as important as the power and data they deliver.

Basic Power Delivery Characteristics of PoE and PoDL

Before delving into the protection considerations that need to be made for PoDL and PoE systems, an outline of the fundamentals of each power delivery method is helpful. Both technologies are built on the concept of delivering power and data over the same physical medium, but they differ in key aspects such as voltage levels, power capacity, and cabling infrastructure. These differences directly influence how they must be protected.

PoE is commonly deployed in enterprise and consumer environments to power devices like wireless access points, VoIP phones, and security cameras. It typically operates at voltage levels between 44 and 57 V, with newer implementations such as the IEEE 802.3bt (PoE++) standard capable of delivering up to 90 W of power at the source.

That higher power capacity enables PoE to support more demanding devices, including high-resolution cameras and smart building infrastructure. Built-in classification and negotiation protocols help ensure that power is delivered safely and appropriately based on the receiving device’s requirements.

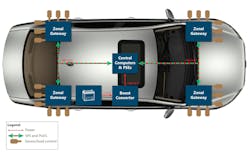

In contrast, PoDL is engineered for more specialized use cases — particularly in the automotive and industrial sectors — where space, weight, and power efficiency are critical. PoDL systems deliver power at lower voltages, typically in the range of 12 to 58 V, and they’re optimized for lower-power devices like sensors, actuators, and control modules.

The IEEE 802.3cg standard calls for a maximum power output of 52 W. The focus here is less on raw power and more on delivering just enough energy to support reliable operation in compact and sometimes harsh environments. Although, this may change given the automotive space trending toward zonal control; higher power usage (more than 52 W) of PoDL may be necessary.

These differences are also reflected in the cabling infrastructure used by each system. PoE relies on standard Ethernet cabling, which is most commonly Cat5e or Cat6 that includes four twisted pairs.

Depending on the standard and configuration, power may be delivered over two or all four of those pairs, with connectivity handled through the familiar RJ45 connector. This makes PoE easy to integrate into existing network infrastructure and well-suited for deployments where installation speed and flexibility are important.

PoDL, however, uses SPE cabling, which significantly reduces both the size and weight of the cable. This is especially advantageous in automotive and industrial settings where cabling space is limited, and wiring harness complexity needs to be minimized. The connectors used in PoDL applications are purpose-built for durability and reliability, often designed to withstand vibration, moisture, and extreme temperatures — factors not typically encountered in enterprise PoE environments.

Understanding these foundational differences in power levels, cabling, and operating environments is fundamental when evaluating protection requirements. The electrical risks, fault scenarios, and environmental stresses that PoE and PoDL systems face vary widely, and the protection strategies must be specifically tailored to ensure system safety, reliability, and compliance.

PoE and PoDL: Different Power Characteristics, Similar Protection Schemes

Despite the differences in voltage levels, power capacity, and cabling infrastructure between PoE and PoDL, both systems still rely on a common set of core protection principles. Delivering power and data over the same medium introduces inherent electrical risks. Thus, both technologies implement carefully engineered mechanisms and devices to ensure safe and reliable operation across diverse environments.

One key area of similarity is the initial detection and classification process. Before any power is applied, both PoE and PoDL systems perform device detection to verify that the connected device is compatible and capable of receiving power. This handshake prevents power from being sent to non-compliant or sensitive equipment.

Following detection, a classification stage identifies the power requirements of the connected device. It thus allows the system to deliver only the necessary amount of current, ensuring both energy efficiency and device safety.

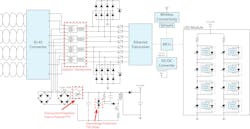

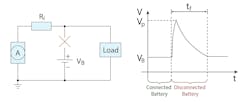

Protection shared by both technologies is for physical overcurrent and overvoltage protection devices. Overcurrent protection is necessary to limit the amount of current delivered over the cable to prevent overheating, potential fire hazards, or damage to the connected device. This is typically accomplished with traditional fuses or polymer PTC resettable fuses.

Overvoltage protection is also vital to maintain system reliability. With long cable lengths and possible human contact comes inherent voltage transients from lightning or electrostatic discharge (ESD), among other sources.

Devices that are commonly used to protect against overvoltage events are transient-voltage-suppression (TVS) diodes, gas discharge tubes (GDTs), and varistors. These devices either clamp or crowbar excess energy away from subsystems, with varying levels of parasitic capacitance and working voltage values.

Whether it’s overcurrent or overvoltage components, both PoDL and PoE use both to accomplish excellent protection for both sides of the power connection.

Lastly, electrical isolation plays an essential role in maintaining system integrity. Both technologies typically incorporate transformers or capacitors to separate the power source from the powered device. This not only helps prevent ground loops and unwanted current paths, but it also protects sensitive equipment from voltage spikes or surges that may occur on either end of the connection.

By implementing these shared protection strategies — detection, classification, overcurrent, and overvoltage protection, and electrical isolation — engineers can uphold PoE and PoDL design goals of safety, reliability, and compliance, regardless of their vastly different application domains.

Do PoE and PoDL Have Unique Protection Requirements?

While PoE and PoDL share many foundational protection mechanisms, such as detection, overcurrent and overvoltage protection, and electrical isolation, the differences in their intended use cases lead to distinct protection requirements. These variations stem largely from the environments where each system operates, as well as the differing demands placed on performance, durability, and safety.

A key distinction lies in each technologies’ physical and electrical environments. PoE systems are typically deployed in controlled indoor settings like offices, schools, or data centers, where temperature, humidity, and electrical noise are relatively stable. As a result, the protection mechanisms in PoE can focus more on compliance with network standards and basic electrical safety.

PoDL, in contrast, is engineered for harsh, often unpredictable environments such as automotive, industrial, and outdoor applications. These settings expose equipment to extreme temperatures, vibration, moisture, and EMI. As a result, PoDL systems require far more robust protection against environmental and electrical stresses, including advanced EMI shielding and thermal-management solutions to ensure consistent performance and reliability.

This environmental contrast also extends to surge and transient protection. PoE typically requires basic surge protection as defined by IEC 61000, which is sufficient for indoor installations. However, PoDL systems must meet much more rigorous automotive and industrial standards such as ISO 7637-2 and ISO 16750-2 load dump waveforms. These standards demand enhanced protection circuitry capable of withstanding high-energy pulses and repeated transients without performance degradation.

Finally, connector safety reflects the different demands of each system. PoE uses standard RJ45 connectors, which include inherent isolation and are well-suited for clean, indoor installations. These connectors are widely adopted and incorporate built-in protections against incorrect insertion and electrical faults.

PoDL, however, may use more specialized connectors that must meet stringent automotive or industrial standards. These connectors often need additional protection against moisture ingress, vibration, arcing, and contamination, ensuring long-term reliability even in the most demanding conditions.

In short, while the protection strategies of PoE and PoDL are built on similar principles, the specific implementations diverge significantly due to the differing operational environments and performance expectations. Understanding these differences is essential for designing systems that are not only functional, but also safe and reliable throughout their lifecycle.

Digitally Integrated PoE and PoDL Systems Rise to the Complexity

In reviewing the evolution of digitally integrated, power-aware PoE and PoDL systems, it becomes clear that while the concept of powering devices over communication lines isn’t new, the complexity of modern systems — and the demands placed on them — have increased dramatically.

From basic detection and overcurrent and overvoltage protection to differing test waveforms and environmental shielding, PoE and PoDL each have unique operational demands that need tailored solutions. But they remain united by a common engineering goal: enabling safe, reliable, and efficient connectivity.

As Ethernet expands into new domains, reaching further into industrial automation, automotive platforms, and smart infrastructure, the importance of understanding and implementing robust circuit protection strategies will only grow. Whether you're designing a secure office network or a resilient in-vehicle system, the principles explored here serve as a foundation for building systems that last.

Ultimately, by recognizing the evolving protection needs of these technologies, engineers and system designers are better equipped to build the next generation of intelligent, power-aware networks. These new networks are expected to, much like POTS once did, quietly power our world in the background while keeping us connected.

>>Download the PDF of this article

About the Author

Jed Boyer

Power Applications Engineer, Bourns Inc.

Jed Boyer serves as a Power Applications Engineer at Bourns, with the responsibility to help design innovative circuit protection solutions that ensure reliability and safety. Boyer’s experience includes helping customers with component selection and collaborating on application-specific designs. He holds a BSEE from the University of Illinois at Urbana-Champaign.